Note: Sealing an aluminum disk onto a plastic cap

Objective:

Seal an aluminum disk onto a plastic cap at a rate of 90 per minute for an application in the bottling industry

End Product:

Bottle cap

Equipment:

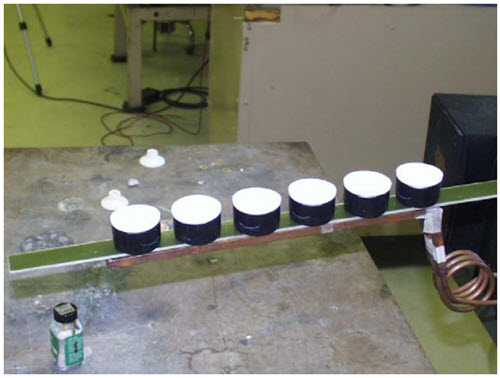

- Ambrell EKOHEAT 30 kW, 50 to 150 kHz induction heating system equipped with a remote heat station containing six 1.0 μF capacitors.

- A single position, one turn 12” helical coil designed and developed for this application.

Materials:

- Plastic cap (top and bottom) with an outside diameter of 1.85” (47 mm)

- Aluminum disk with an outside diameter of 0.8” (20 mm)

Temperature:

300 ºF (149 ºC)

Frequency:

80 kHz

Testing:

The aluminum disk was placed into the top cap and the bottom cap was threaded onto the top. The cap was then placed 1/8” (3.2 mm) away from the coil. The EKOHEAT was turned on and the cap heated to the target temperature in three seconds.

This process resulted in a strong bond between the plastic and the aluminum. With the 12” (305 mm) coil that can heat multiple caps at the same time and a heating time of three

seconds, the targeted production rate of 90 caps per minute can be achieved and exceeded.

Benefits:

-

Precise heating: Induction heating enabled the aluminum to seal to the plastic cap quickly without the cap being damaged.

-

Speed: The customer desired a quick rate which would make in-sourcing the process worthwhile, and induction heating exceeded the targeted production rate thanks to its fast heating.

-

Clean and flameless heating: Given the plastic cap, clean, flameless heating was required to maintain its integrity.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000