Note: How to braze a copper tube

Objective:

To heat a copper tube to 1500 °F (816 °C) for a brazing application

End Product:

Swimming pool heaters and pumps

Equipment:

Ambrell EASYHEAT 10 kW, 150 to 400 kHz induction heating system equipped with a remote workhead containing two 1.5 uf capacitors for a total of 0.75 uf A single position six-turn split helical induction heating coil designed and developed specifically for this application

Materials:

Copper tubes (0.87 in /22 mm O.D.) Braze wire

Temperature:

1500 °F (816 °C)

Frequency:

200 kHz

Testing:

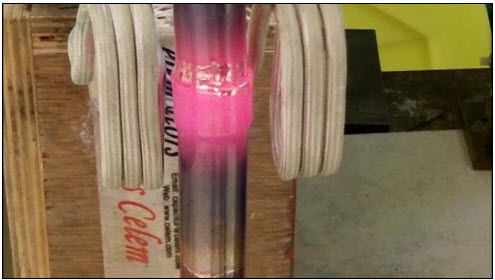

The braze preforms were positioned on the tube, and the assembly was then placed in the coil. After 30 seconds of heating, the braze alloy had melted and flowed into the joint area. The power was then turned off and the process was completed.

Benefits:

-

Speed: The client had been using a torch, which took 50 seconds instead of 30

-

Precise, repeatable heating: The main reason that the client turned to induction was to increase repeatability and in turn boost part quality

-

Safety: There is no open flame with induction, which makes it a safer method of heating than torch heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000