Note: Heat a compacted litz wire bundle for stripping

Objective:

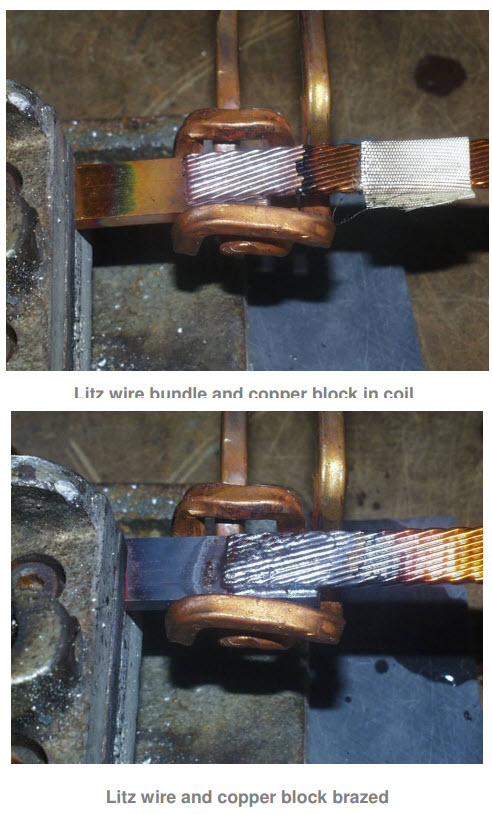

To heat a compacted litz wire bundle for wire stripping then braze the litz wire bundle to a copper block for use in an automotive motor.

End Product:

Litz wire bundle

Equipment:

Ambrell 5.6 kW induction heating system, equipped with a remote workhead containing two 1.5 μF capacitors for a total of 0.75 μF An induction heating coil designed and developed specifically for this application.

Materials:

Compacted litz wire bundle 0.388 in (9.85 mm) wide, 0.08 in (2.03 mm) thick copper bar 0.5 in (12.7 mm) wide, 0.125 in (3.17 mm) thick and 1.5 in (38.1 mm) long

braze wire & white flux

Temperature:

1400 °F (760 °C)

Frequency:

300 kHz

Testing:

A three-turn helical coil is used for the wire stripping process. The litz wire bundle is placed in the coil for 3 seconds to strip the lacquer 0.75 in (19mm) from the end of the bundle. The wire bundle is then scraped with a metal brush to remove the burnt lacquer. For the brazing process a two turn channel coil is used. The litz wire and copper assembly are placed in the coil and the braze wire is fed by hand. The braze is completed in 45-60 seconds.

Benefits:

-

Consistent, repeatable results

-

Faster process time, increased production

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000