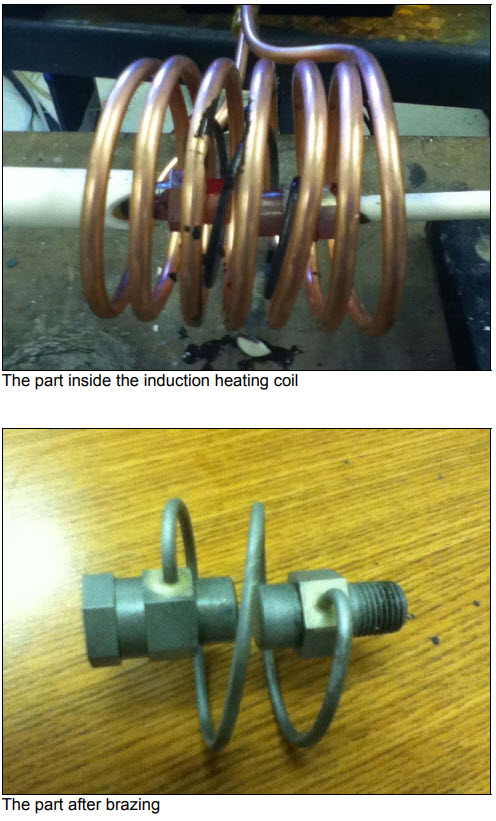

Note: Brazing two fittings and a helical tube to a mount

Objective:

To heat two fittings and a small helical tube (a steady mount for a compressor) to 1350 °F (732 °C) for brazing

End Product:

Compressor mount

Equipment:

Ambrell EKOHEAT 10/100c, 10 kW 50-150 kHz induction heating system equipped with a remote heat station containing three 1.0 μF capacitors A single position seven-turn helical coil designed and developed for this application

Materials:

Stainless steel fittings Stainless steel small helical tube Braze Flux

Temperature:

1350 °F (732 °C)

Frequency:

50 kHz

Testing:

The parts were fluxed and assembled. Two braze pre-forms were created. The assembly was placed into the coil and the power was turned on. After 45 seconds the braze alloy had flowed into the joint, which created a good fillet and a leak-proof joint.

The part was cooled and then tested to verify the tube had not been blocked. Milk of Magnesia is effective in stopping the braze flow from blocking the tube.

Benefits:

-

Quality: The client had been using a torch, and was dealing with inconsistent results that impacted part quality

-

Speed: Induction heats the assembly more quickly than the torch

-

Production rate: Faster heating leads to a superior production rate

-

Efficiency: Induction is more energy-efficient than a torch

-

Worker safety: Induction means there aren"t the safety risks that come with an open flame

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000