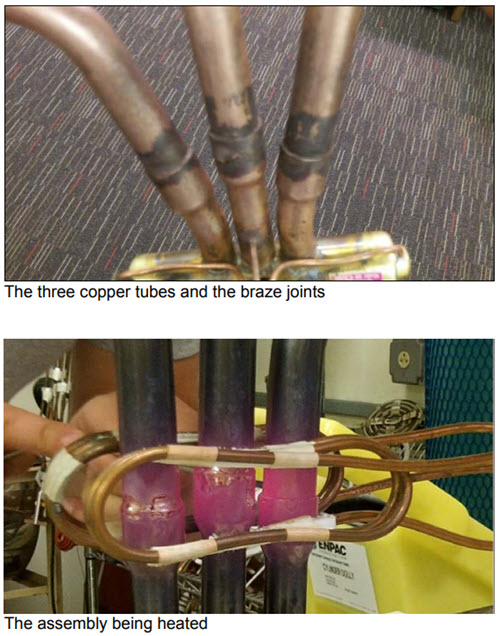

Note: Brazing three copper tubes in a four-way valve

Objective:

Heating three copper tubes to 1500 °F (816 °C) for a brazing application in the heating and cooling industry

End Product:

Copper tubes

Equipment:

Ambrell EKOHEAT 15/100c, 15kW 50-150 kHz induction heating system equipped with a remote heat station containing four 1.0 μF capacitors A single-position six-turn split helical induction heating coil designed and developed specifically for this application

Materials:

Copper tubes Valve body Braze

Temperature:

1500 °F (816 °C)

Frequency:

104 kHz

Testing:

After some testing with lower power units, it was determined that the EKOHEAT 15/100c could heat the part quickly enough to achieve the braze temperature without damaging the plastic in the base. It also prevented thermal conduction to the inner workings of the valve. With the EKOHEAT 15/100c, the heating time was reduced to just less than one minute. The use of a braze pre-form is also recommended to give an ideal braze flow and an accurate amount of braze.

Benefits:

-

Speed: Due to the use of a higher power system, speed expectations were exceeded and improved over the client"s previous method, which was torch heating

-

Part quality: A good braze joint was formed, and induction"s consistency and repeatability proved valuable

-

Safety: Induction doesn"t have an open flame, which results in a safer work environment

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000