Note: Brazing steel orthodontic parts

Objective:

To heat a batch of orthodontic parts to 1300 °F (704 °C) within 1 second in an inert atmosphere for brazing

End Product:

steel orthodontic parts

Equipment:

Ambrell 3kW induction heating system and 0.5μF heat station

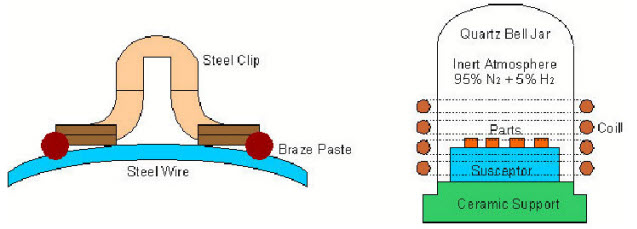

Materials:

Small stainless steel orthodontic parts

silver braze alloy, no flux

3.125 in (79.3 mm) graphite susceptor disk with 1 in (25.4 mm) center hole

bell jar made of pyrex or quartz

Temperature:

1300 °F (704 °C)

Frequency:

165 kHz

Testing:

A four turn helical coil is used to heat parts. Brazing paste is applied to orthodontic parts with a syringe. The parts are placed on the graphite susceptor disk, which is placed on an insulating support in a quartz bell jar. After the jar is filled with inert gas, RF power is applied for 50 seconds at 165kHz to reach the required temperature, followed by a cool-down cycle.

Benefits:

Fast, accurate, repeatable heat

Ability to heat very small areas within precise production tolerances

Better joint quality, reduced oxidation

Increased production rates and reduced labor costs (100 parts are brazed in 50 seconds)

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000