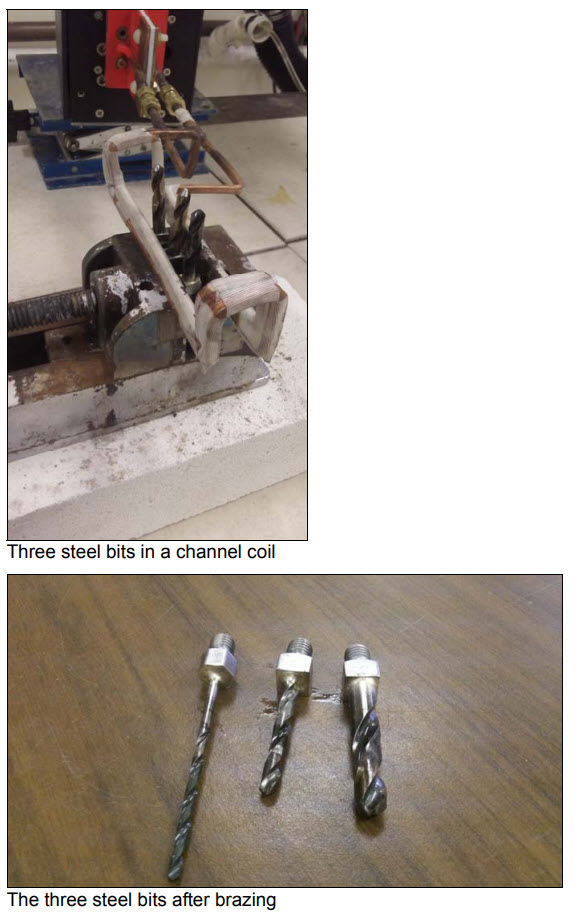

Note: Brazing steel drill bits (aerospace)

Objective:

To heat multiple size/style drill bits to 1300 °F (704 °C) for a brazing application

End Product:

Steel bits

Equipment:

Ambrell EKOHEAT 15/100c, 15kW 50-150 kHz induction heating system equipped with a remote heat station containing four 1.5 μF capacitors A single-position six-turn helical induction heating coil designed and developed specifically for this application

Materials:

Steel bits Wire Braze rings Flux

Temperature:

1300 °F (704 °C)

Frequency:

219 kHz

Testing:

The steel bits were pre-fluxed and braze rings were placed around the joint area of each part. The parts were heated to temperature and braze began to flow. The parts were then cooled and rinsed with hot water. The parts heated to temperature within 30 seconds. Up to five parts can be heated at the same time with this process.

Benefits:

-

Speed: The client wanted the parts to be heated within 30 seconds, and induction achieved that objective

-

Increased production: The client wanted to heat three parts concurrently, and this process allowed up to five parts to be heated concurrently

-

Repeatability: The process is repeatable which means the client can expect consistent results with each part, which wasn"t achieved when they were using a torch

-

Safety: Induction heating doesn"t present an open flame like a torch does

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000