Note: Brazing stainless steel orthodontic begg brackets

Objective:

To heat a steel dental assembly to 1400 °F (760 °C) for brazing

End Product:

Orthodontic begg brackets

Equipment:

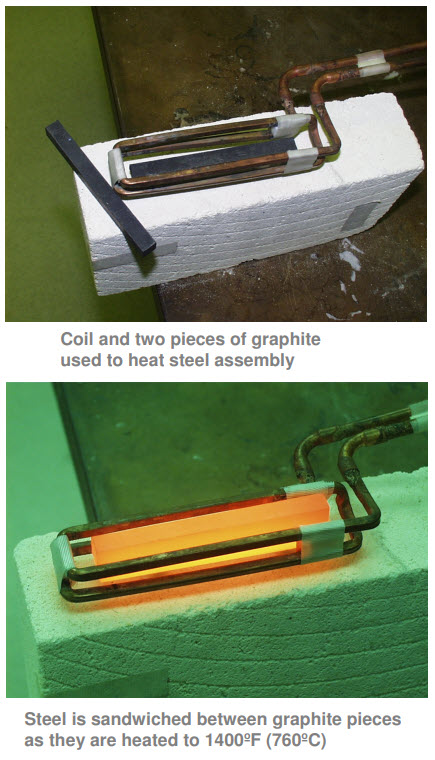

Ambrell 2.0 kW induction heating system, equipped with a remote workhead containing two 0.33 μF capacitors for a total of 0.66 μF An induction heating coil designed and developed specifically for this application.

Materials:

Stainless steel plates 0.118 in (3mm) square and 0.078 in (2mm) high stainless steel hook mesh two pieces of graphite 0.375 in (9.5mm) square cross section 4 in (101.6mm) long white flux for brazing

Temperature:

1400 °F (760 °C)

Frequency:

206 kHz

Testing:

A two turn oblong helical coil is designed to heat the steel brackets which are sandwiched between the two pieces of graphite. The heat will be transferred from the graphite to the steel bracket assemblies to reach 1400 °F (760 °C) in 120 seconds. There is a cool down time of 30-50 seconds before the steel can be removed from the graphite sandwich.

Benefits:

-

Braze flow is consistent and controllable by using braze pieces

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000