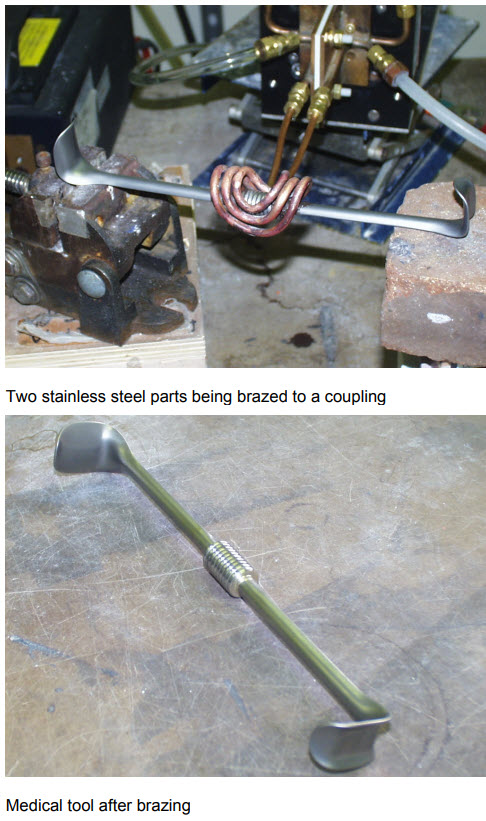

Note: Brazing stainless steel medical tool parts

Objective:

Braze two parts to a coupling with an outside diameter of 0.5" (13 mm) to create a medical tool. The client's goal was to braze both parts concurrently as quickly as possible with maximum repeatability.

End Product:

Medical tool

Equipment:

Ambrell EASYHEAT 3542 LI, 3.5 kW induction heating system, equipped with a remote workhead containing one 1.5 μF capacitor. A single position, two turn C-shaped coil designed and developed specifically for this application.

Materials:

Two stainless steel parts A coupling Black flux Braze rings

Temperature:

1250 °F (677 °C)

Frequency:

181 kHz

Testing:

Two braze rings were applied to the coupling, the joints areas were fluxed and the two parts were put inside the coupling and heated. The assembly was heated to the desired braze temperature within 20 seconds. After brazing the parts to the coupling, it was rinsed with water and cleaned with a hand pad.

Benefits:

-

Time savings: Braze temperature was reached quickly which saves time when compared to other heating methods

-

Precision and efficiency: Direct and precise control of heat saves energy when compared to other heating methods

-

Joint quality: The braze alloy forms a good joint, validating the high quality level that can be achieved via induction

-

Easy process integration: Can easily be integrated into an automated process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000