Note: Brazing Stainless Steel Conduit to a Ferrule and Elbow Assembly

Objective:

To heat a stainless steel conduit, ferrule and elbow assembly to 1400 °F (760 °C) within 20 seconds for brazing.

End Product:

Stainless steel conduit

Equipment:

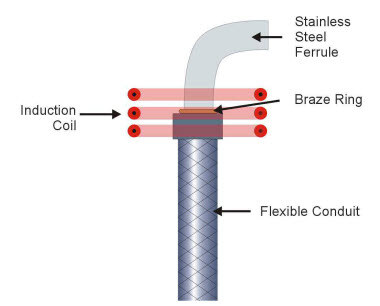

Ambrell 3.5 kW induction heating system equipped with a remote workhead

An induction heating coil designed and developed specifically for this application.

Materials:

6 in (152.4 mm) l x 0.5 in (12.7 mm) âÂÂ

stainless steel conduit

0.5 in (12.7 mm) l x 0.5 in (12.7 mm) âÂÂ

ferrule,

2 in (50.8 mm) elbow with 0.5 in (12.7 mm) âÂÂ

Temperature:

1400 °F (760 °C)

Frequency:

273 kHz

Testing:

A specially designed, three-turn helical coil is used to provide heat to the assembly at the braze joint area. Two small silver solder braze rings are placed at each joint; the joints are coated with black flux to insure that the braze material flows cleanly. The assembly is placed inside the coil and power is applied for 15 seconds to cause the braze to flow.

Benefits:

- Consistent and repeatable results

- No flame process

- Faster process time

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000