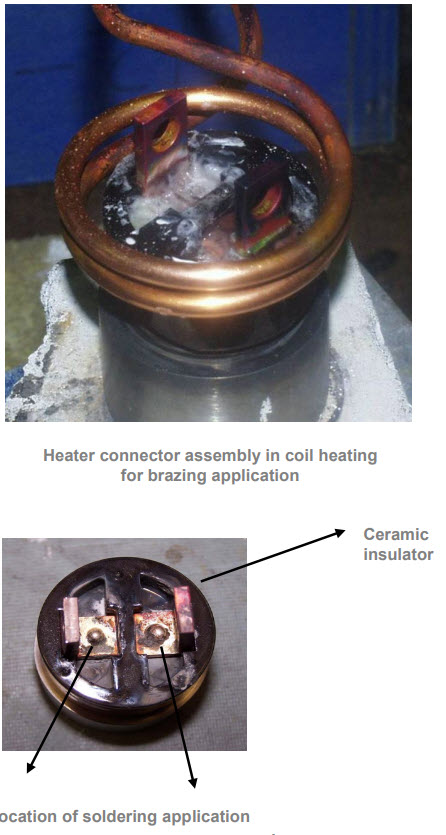

Note: Brazing joint on pressurized heater connectors

Objective:

To braze a joint between a copper lug and nickel-plated copper pins on a pressurized heater connector

End Product:

Pressurized heater connector

Equipment:

Ambrell EASYHEAT 10 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

1.5 in (38.1mm) diameter heater connector in a ceramic insulator with L-shaped copper lugs and nickel-plated copper pins silver solder braze

Temperature:

1175-1375 °F (635-746 °C)

Frequency:

270 kHz

Testing:

A two-turn helical coil was used to heat the copper lugs and nickel-plated copper pins for one minute. A clamp was used in production to hold the copper lugs in place for brazing.

Benefits:

-

Minimal transfer of heat to the adjacent ceramic insulator.

-

Hands-free heating that involves minimal operator skill for manufacturing

-

Flameless processing. Heat very small precise areas within production tolerances.

-

Even distribution of heating.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000