Note: Brazing Hydraulic Hose Assemblies

Objective:

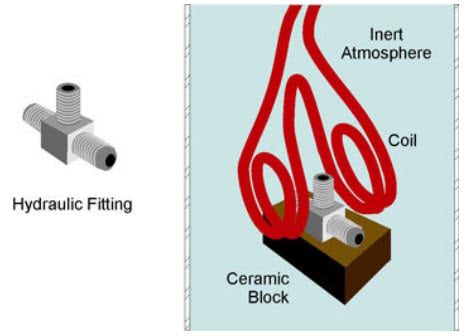

To heat a steel hydraulic hose fitting in an inert atmosphere to 2200 °F within 7 seconds for brazing without any carbon buildup.

End Product:

Hose fitting

Equipment:

Ambrell 3.5 kW heating susyem

remote heat station containing one 1.0 μF capacitor and a specially designed induction coil.

Materials:

Three-opening steel hydraulic fitting

pure copper braze paste

Temperature:

2200 °F

Frequency:

283 kHz

Testing:

A specially-designed, four-turn split helical coil was used to provide optimal heating to the joint area of the hydraulic fitting. The testing was done in the ABS Mark 2 containing a mixture of 95% Argon and 5% Hydrogen gas. RF power from the Ambrell 2kW heated the steel assemblies to 2200 °F within 7 seconds. An infrared pyrometer was used to measure the temperature of the part. After the copper braze flowed, the parts were allowed to cool and were removed from the bell jar

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000