Note: Brazing Fishhooks

Objective:

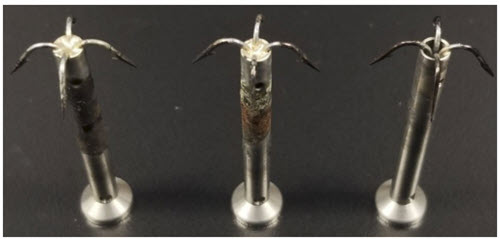

To heat two pairs of fishhooks inside a steel tube for a brazing application. The end product is an anchor.

End Product:

anchor

Equipment:

Ambrell EASYHEAT 1.2 kW, 150-400 kHz solid state induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Magnetic steel fishhooks and non-magnetic steel tubes

Temperature:

1200 °F (649 °C)

Frequency:

281 kHz

Testing:

There were three assemblies heated for this application. A customdesigned single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took 35 seconds or less to heat each sample to temperature. For one of the samples, to prevent overheating of the tube, braze wire was cut up and put inside the tube along with the fishhooks. That way, the entire assembly would get up to temperature at the same time. Doing this improved the heating time to 23 seconds. THE LAB confirmed the feasibility of the heating process for heating the fishhook samples to temperature for brazing.

Benefits:

Speed: While this was a new process for the client, it achieved their time objectives.

Precision: Induction heats only the area of the fishhook that requires it for brazing.

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating, which is not the case with many alternative heating methods.

Lab Expertise: THE LAB at Ambrell designed a solution that met the client"s objectives so they had peace of mind before investing in a system.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000