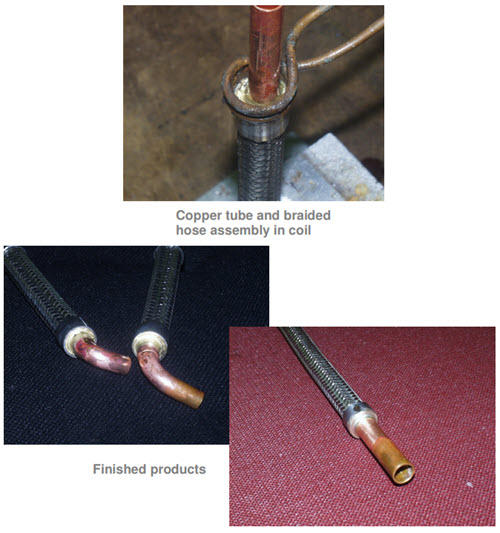

Note: Brazing Copper Tubes to a Braided Stainless Steel Hose

Objective:

Brazing a copper tube to each end of a braided stainless steel hose

End Product:

Copper tubes with braided hose

Equipment:

Ambrell 2.4 kW induction heating system, equipped with a remote workhead containing two 0.33 μF capacitors for a total of 0.66 μF An induction heating coil designed and developed specifically for this application.

Materials:

Copper tubes, 0.5 in (12.7mm) diameter, 0.9 in (22.86mm) diameter braided stainless steel hose, braze preforms and black flux

Temperature:

1400 °F (760 °C)

Frequency:

380 kHz

Testing:

A two turn helical coil is used to braze the assembly. Braze ring is placed around the joint area and the part is fluxed. The assembly is heated for 80 seconds to flow the braze and complete the joint. Customer is currently using flame and a highly paid operator to complete this application. By purchasing the induction equipment for this application and replacing the highly paid operator with a less skilled operator, the customer can save approximately $20,000/year in operator cost alone, not factoring in any energy savings. The induction equipment will pay for itself in the first 7 months of operation.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Delivers heat only where needed; Rapid localized heating

-

Produces clean and controllable joints

-

Repeatable and consistent results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000