Note: Brazing copper bars & copper slip ring (motors)

Objective:

Heating a copper slip ring for brazing 52 vertical copper bars for refurnishing 5MW motor assemblies

End Product:

Motor assembly

Equipment:

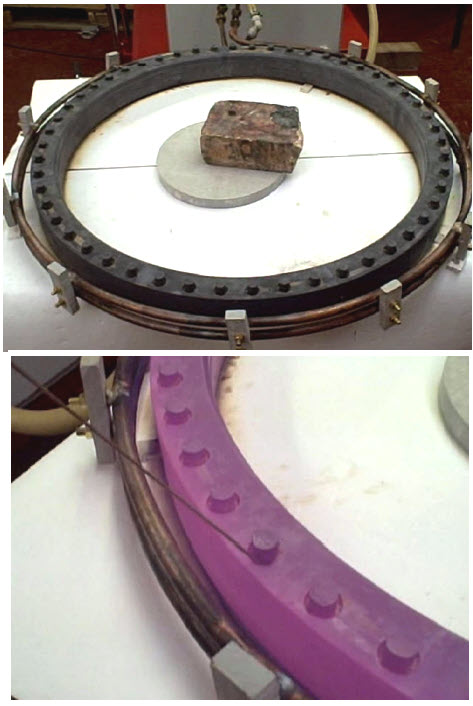

Ambrell 200 kW, 10 kHz induction heating system, equipped with a remote workhead containing two 30.47 μF capacitors for a total of 60.95 μF An induction heating coil, designed and developed specifically for this application.

Materials:

Copper slip ring 1.8 in (45mm) thick, 2.8 in (70mm) wide with a diameter of 27.5 in (700mm), Copper vertical bars and silver copper braze

Temperature:

1256 °F (680 °C)

Frequency:

10 kHz

Testing:

A three turn helical coil is used to heat the slip ring. Power is applied for 25 minutes to bring the ring up to brazing temperature. The slip ring is then held at temperature as the self locating 52 vertical bars are brazed into place.

Benefits:

-

Much faster process time compared to the current process of using gas to braze each joint individually

-

Reduced energy cost

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000