Note: Brazing copper and steel tubes (HVAC)

Objective:

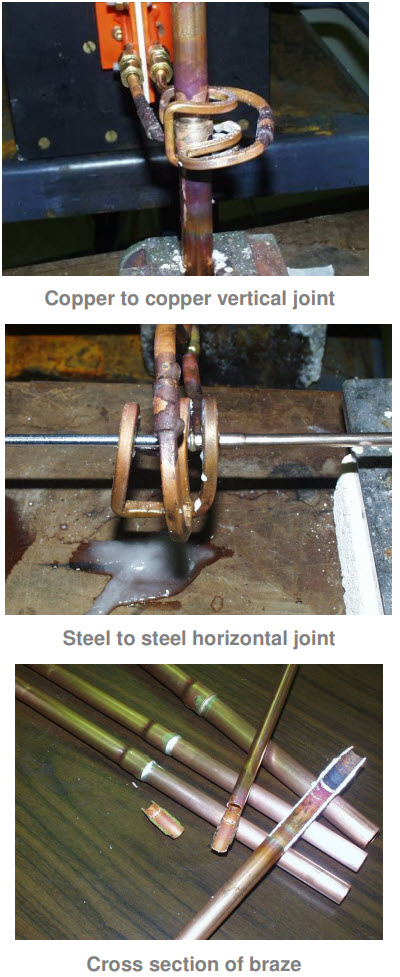

Brazing various diameters and combinations of copper and steel tubing in vertical and horizontal alignments

End Product:

HVAC components

Equipment:

Ambrell 30 kW induction heating system, equipped with a remote workhead containing eight 1.0 μF capacitors for a total of 8.0 μF An induction heating coil designed and developed specifically for this application.

Materials:

Sample combinations: 1. copper 5.9 in (150mm) x 0.37 in (9.5mm) dia, copper 5.8 in (148mm) x 0.37 in (9.5mm) dia with enlarged end of 0.44 in (11.2mm) dia 2. copper 5.9 in (150mm) x 0.5 in (12.7mm) dia, copper 5.8 in (148mm) x 0.5 in (12.7mm) dia with enlarged end 0.56 in (14.3mm) 3. copper 5.9 in (150mm) x 0.6 in (15.8mm) dia, copper 5.8 in (148mm) x 0.6 in (15.8mm) with enlarged end 0.7 in (18.2mm) 4. steel 5.3 in (136mm) x 0.16 in (4.2mm) dia, steel 5.8 in (147mm) x 0.18 in (4.76mm) dia, enlarged end 0.22 in (5.7mm) dia 5. steel 5.7 in (146mm) x 0.18 in (4.76mm) dia, copper 3.85 in (98mm) x 0.18 in (4.76mm) dia, enlarged end 0.23 in (6.0mm) dia 6. copper 3.96 in (100.6mm) x 0.25 in (6.35mm), copper 3.88 in (98.6mm ) x 0.25 in (6.35mm), enlarged end 0.3 in (7.7mm) dia 7. copper 3.96 in (100.6mm) x 0.25 in (6.35mm) dia, copper 1.8 in (45.7mm) x 0.31 in (7.94mm) dia Flux and braze preforms

Temperature:

1350 °F ( 732 °C)

Frequency:

105 kHz

Testing:

A two turn in C in coil is used to braze all seven sample combinations. Each sample combination is fluxed and a braze preform is placed at the joint location. Each sample combination is brazed in the vertical and also in the horizontal orientations due to the locations of the tubing in the customers' assembly. Braze time ranges from 5.5 to 22 seconds depending on the material and diameter of the sample combination Customer is currently using flame brazing for this application. Application is being done in a large facility and customer will gain safety benefits such as no hazardous fumes or open flames with induction. Customer came to Ambrell because of the portable brazing system which saves the customer time and money because of the orientation and tight locations of their braze joints.

Benefits:

Hands-free heating that involves no operator skill for manufacturing

Repeatable, consistent results

Ability to braze in tight areas without affecting surrounding materials

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000