Note: Brazing Copper T Assemblies

Objective:

To heat copperT-assemblies for brazing

End Product:

Copper T assembly

Equipment:

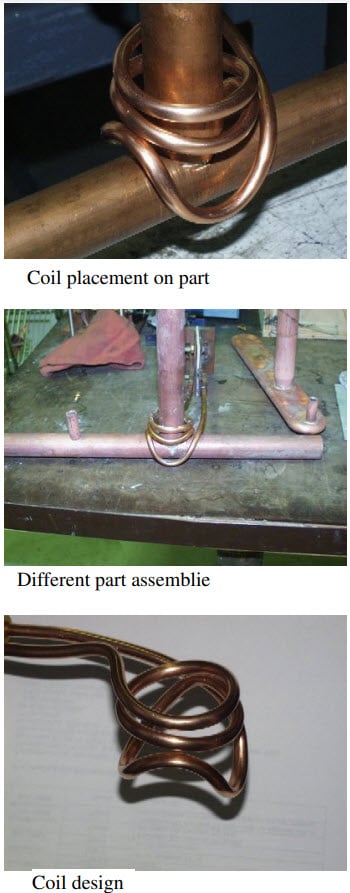

Ambrell 20 kW, 50-450 kHz solid state induction power supply with a remote heat station containing two 1.32 μF capacitors (total capacitance 0.66 μF). A custom-designed induction heating coil.

Materials:

Copper inT in assemblies Silver-copper eutectic braze White flux

Temperature:

1400(760) °F( °C)

Frequency:

250 kHz

Testing:

A custom double-wound pancake-helical coil combination is used to efficiently transfer RF power. Tests were conducted using temperature indicating paint to establish heating profiles and time-to-temperature. After the optimum time-to-temperature of 3-5 minutes is established, a braze ring is placed at the joint and white flux applied to the joint area. The first joint on each piece takes 5 minutes with subsequent joints on the same copper piece taking much less time (~3 minutes)

Benefits:

-

Semi-automatic process reduces amount of operator labor involved

-

Easy and effective completion of braze joints

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000