Note: Brazing brass bellows (pneumatic regulators)

Objective:

Brazing a series of brass bellow assemblies for pneumatic regulators

End Product:

Brass bellows assembly

Equipment:

Ambrell 15 kW induction heating system, equipped with a remote workhead containing three 1.5μF capacitors for a total of 4.5μF An induction heating coil designed and developed specifically for this application.

Materials:

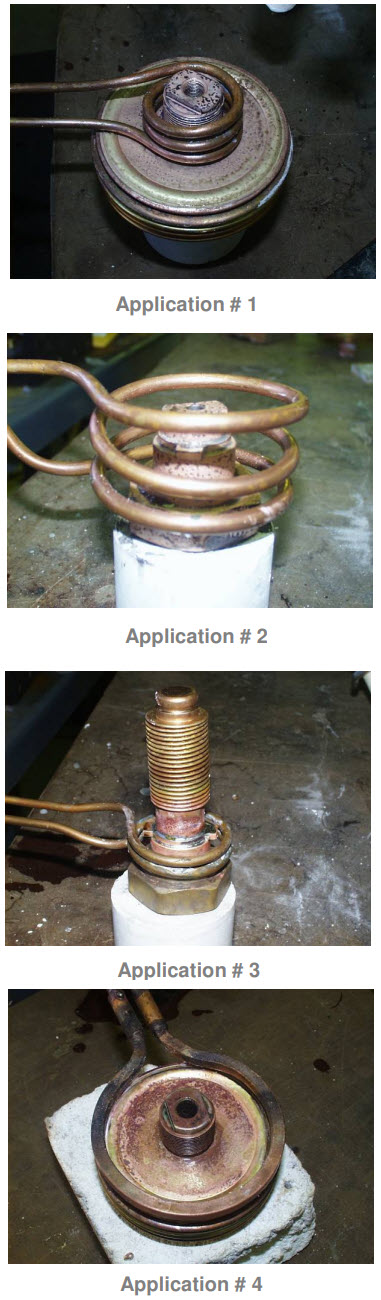

Four different assemblies: 1. flange 3.62 in (91.9 mm) dia, threaded stud .74 in (18.8 mm) x 2 in (50.8 mm) (brazing) 2. bonnet sub assembly 1.89 in (48 mm) dia, 1.75 in tall (44.5 mm) (brazing 3 joints simultaneously) 3. bonnet sub assembly to bellows assembly 1.125 in (28.6 mm) OD x 4.14 in (105.2 mm) tall (soldering) 4. flange to flange 3.62 in (91.9 mm) dia x 1.36 in (34.5 mm) tall (brazing)

Temperature:

460 °F (238 °C) soldering, 1200 °F (648 °C) brazing

Frequency:

130, 92, 145 & 127 kHz

Testing:

There are four different brazing/soldering applications and each one requires a different coil. The coils range from a single turn to a three turn helical coil. Application # 1 (flange and threaded stud) requires a three turn helical coil and 90 seconds to complete the braze. Application # 2 (bonnet sub assembly with three joints) requires a three turn helical coil and 120 seconds to braze the three joints Application # 3 (bonnet sub assembly and bellow assembly) requires a two turn coil and 20 seconds to flow the solder preform. Application # 4 (flange to flange) requires a single turn helical coil and rotation of the part to uniformly heat the part and braze the joint. Heat cycle is 60 seconds Customer is currently using a flame to braze/solder these parts and manufacture approx. 600 total parts per month. They are not looking to increase their production but are looking for a repeatable and reliable process. These are aircraft parts and must be leak tested. The customer is looking to improve their rejection rate, reduce scrap and labor and improve profitability.

Benefits:

-

Rapid localized heating only where needed

-

Creates clean, controllable joints

-

Non-contact, energy efficient heat without flame

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000