Note: Brazing Brass and Copper Nozzles

Objective:

To heat brass and copper samples for a brazing application in the aerospace industry; the client has been using a torch but wanted more consistent, higher quality parts

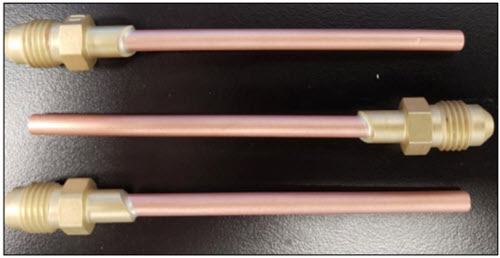

End Product:

Brass, copper nozzles

Equipment:

Ambrell EASYHEAT 6 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Brass and copper parts

Temperature:

1200 °F (649 °C)

Frequency:

206 kHz

Testing:

A custom-designed multiple-turn helical coil was built to generate the required heat for the application. Temperature indicating paint was then applied to the part, which dissolves when the part reaches temperature. It took about 120 seconds to heat the part to temperature. The speed and end-product met the client's objectives.

Benefits:

-

Speed: Induction met the client"s time requirements and can be faster than other heating methods.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating, which was a primary reason this client was interested in induction.

-

Work Environment: With induction there is no open flame and with induction"s instant on/off capabilities, it introduces less heat into the work environment.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000