Note: Brazing automotive tube assemblies

Objective:

To braze a steel tube to a steel fitting

End Product:

Steel fitting

Equipment:

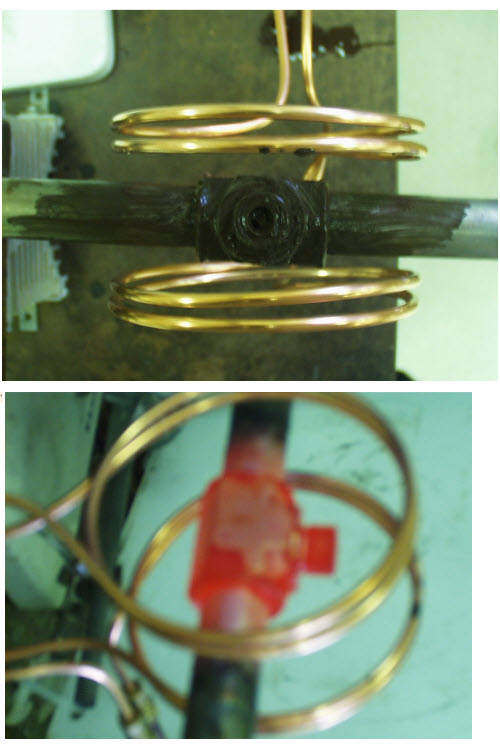

Ambrell 5.0 kW induction heating system, equipped with a remote workhead containing two 1.0 μF capacitors for a total of 0.5 μF An induction heating coil designed and developed specifically for this application.

Materials:

1 in (25.4 mm) diameter steel tubing steel fitting braze slug black flux

Temperature:

1400 °F (760 °C)

Frequency:

198 kHz

Testing:

A four-turn split-helical coil is used to heat the steel assembly to 1400 °F (760 °C) for 85 seconds. The coil design allows for the steel fitting to expand away from the steel tube which allows braze to flow through the joint. The amount of braze alloy is controlled by the braze slug allowing for an aesthetically pleasing joint.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Precise and uniform distribution of heating

-

The collection of flux on the coil is reduced due to efficient coil design.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000