Note: Brazing aluminum adaptors to aluminum tubes

Objective:

To heat aluminum adaptors and aluminum tubes for a brazing application

End Product:

Truck components

Equipment:

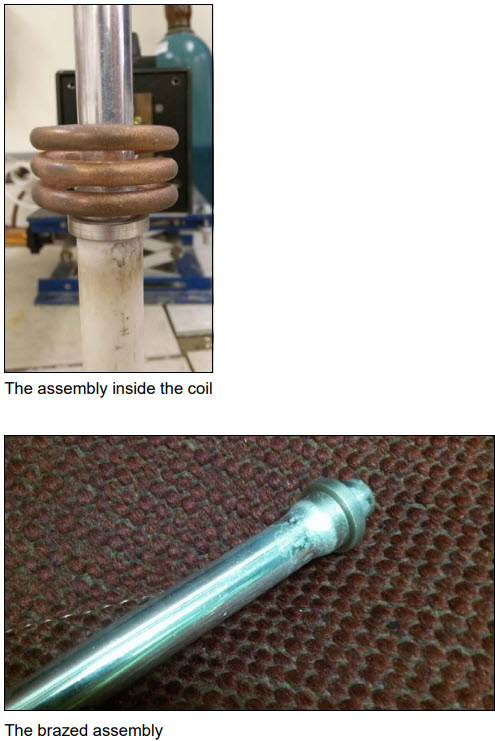

Ambrell EASYHEAT 5 kW, 150 to 400 kHz induction heating system equipped with a remote workhead containing two 1.5 μF capacitors for a total of 0.75μF A multi-turn helical induction heating coil designed and developed specifically for this application

Materials:

Aluminum adaptors in (13 mm) O.D. aluminum tubes

Aluminum braze paste

Temperature:

1100 °F (593 °C)

Frequency:

298 kHz

Testing:

The joint was assembled and aluminum braze paste was applied to the joint area. The assembly was then placed inside the coil and heating began. Testing took place to determine the best cycle time for achieving the objective without melting the aluminum. 55 seconds was determined to be the ideal cycle time. To increase production, a multi-position coil was recommended so multiple parts could be heated while maintaining a cycle time of 55 seconds.

Benefits:

-

Speed: Induction enabled the brazing process to be completed more rapidly than with a torch

-

Consistency: Induction enables consistent joint quality, which a torch often doesn"t deliver

-

Safety: There is no open flame with induction, so it"s a safer heating option than other options such as torch heating

-

Efficiency: Induction delivers heat only where it"s required, making it more efficient than many competitive heating methods

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000