Note: Brazing a steel tube and fitting (automotive valve)

Objective:

To heat a steel tube and fittings to 1350 °F (732 °C) within 1 minute for a brazing application to create a valve for the automotive industry

End Product:

Automotive valve

Equipment:

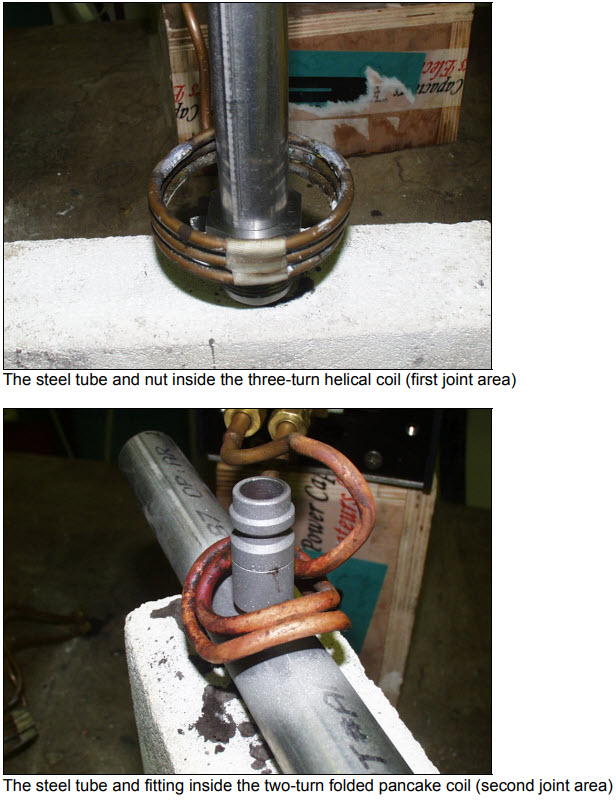

Ambrell EASYHEAT 3542, 3.5kW 150-400 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors A three-turn helical coil to heat the steel nut and steel tube (first joint area) A two-turn folded pancake style coil to heat a fitting and tube (second joint area)

Materials:

Steel tube 1 in (25.4 mm) OD

Steel nut 1.375 in (34.8 mm) OD

Braze wire Black flux

Temperature:

1350 °F (732 °C)

Frequency:

187 kHz (first joint area)/300 kHz (second joint area)

Testing:

For heating the steel nut and tube, the tube was sand blasted in the joint area to remove the coating so the braze material would adhere to the tube. The steel nut and tube were placed together and a braze pre-form was wrapped around the tube. The joint area was fluxed and the assembly was heated. The heating cycle time was 60 seconds. The second joint area on the side of the valve was also sand blasted to ensure good braze adhesion. A braze pre-form was positioned on the nipple of the fitting and the parts were placed together. The joint area was fluxed and the joint was heated. The heat cycle time for this joint was 45 seconds.

Benefits:

-

Customer"s client was unhappy with the results from MIG welding, which drove them to look at induction as an alternative process

-

Induction heating proved to be a fast, repeatable heating method for the application

-

Ambrell"s free Lab Service Request testing enabled them to test their application to ensure induction heating would work for their application

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000