Note: Brazing a steel Nozzle Assembly (Aerospace)

Objective:

To heat a steel nozzle assembly for a brazing application; they had tried an oven and torch but struggled with part quality.

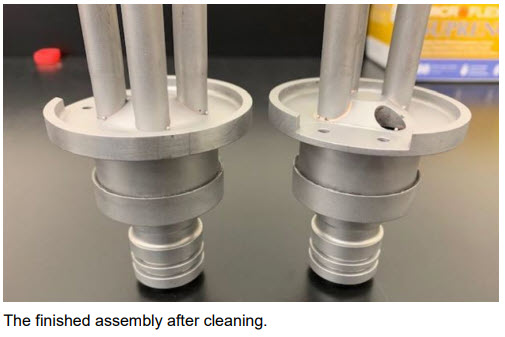

End Product:

Steel nozzle assembly

Equipment:

Ambrell EASYHEAT 4.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Magnetic steel

Temperature:

1450 °F (788 °C)

Frequency:

200 kHz

Testing:

A custom-designed single-position multiple-turn helical coil was built to generate the required heat for the application. This is a low volume application, so heating time was not a priority for the client. The location of the desired braze joint is shielded from the induction field by the lip of the nozzle. The only way to form the braze joint was to heat the assembly together despite the shielded area. The joint area and surface were coated in black flux. The provided braze rings were used. Heating took six minutes, which was long enough that the heat conducted to the joint area to melt the braze alloy ring and form the joint.

Benefits:

-

Repeatability: The client struggled with repeatability with an oven and torch, while induction is a more repeatable process.

-

Work Environment: With induction there is no open flame and with induction"s instant on/off capabilities, it introduces less heat into the work environment.

-

Footprint: Induction is more space efficient than an oven.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000