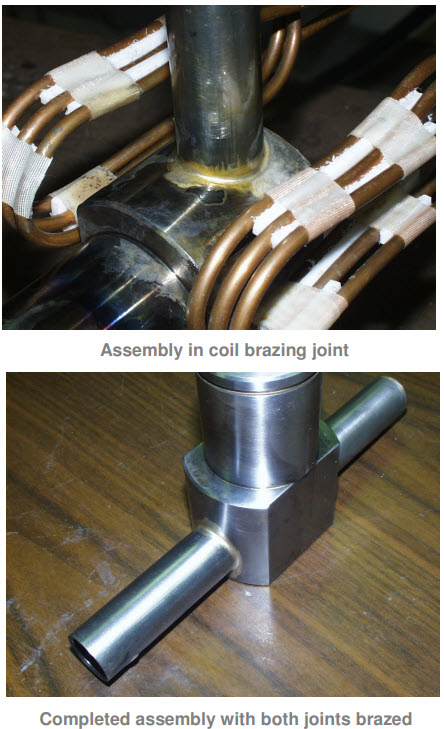

Note: Brazing a spray bar powder coating assembly

Objective:

Brazing two joints on a steel tube assembly used for powder coating

End Product:

powder coatingÄĂÂÄÂĂÂĂÂĂÂÄÂĂÂ tube assembly

Equipment:

Ambrell 15 kW induction heating system, equipped with a remote workhead containing four 1.0 μF capacitors for a total of 1.0 μF An induction heating coil designed and developed specifically for this application.

Materials:

Steel tube .9874 in (25.079mm), 8.74 in (222mm) long, steel block 1.9 in (48.2mm) diameter, 2.75 in (69.8mm) wide, 4.25 in (108mm) tall with a .9876 (25.085mm) diameter hole for the steel tube to slide through

Temperature:

1400 °F (760 °C)

Frequency:

79 kHz

Testing:

A six turn split helical coil is used to braze the tube to the block. The tube is slide through the hole in the block and positioned. Black flux is applied to the joint and a braze preform is placed at the joint location. The assembly is placed in the coil and power is applied for 90 seconds to braze the joint. The assembly is rotated and process repeated to complete the second braze. Customer is currently outsourcing this application. By bringing in-house they will save on inventory build up, transportation cost, time to customer and money. customer found Ambrell on the web and liked the idea that Ambrell's application lab can prove our capability before purchasing.

Benefits:

-

Precise, controllable heat

-

Non-contact, energy efficient heat without flame

-

Produces neat and clean joints

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000