Note: Brazing a rectangular steel part

Objective:

To heat a rectangular steel part to 1400 °F (760 °C) for a brazing application

End Product:

Band saw blade guides

Equipment:

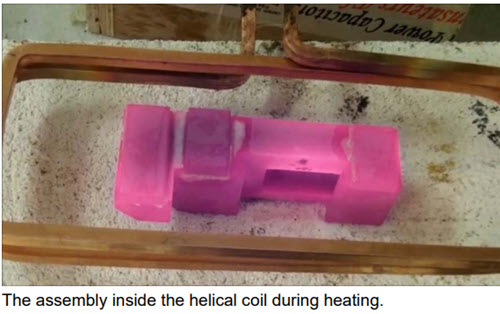

Ambrell EASYHEAT 10 kW, 150 to 400 kHz induction heating system equipped with a remote workhead containing two 1.0 μF capacitors for a total of 0.5 μF A single-position two-turn helical induction heating coil designed and developed specifically for this application

Materials:

Steel part Carbide inserts

Temperature:

1400 °F (760 °C)

Frequency:

232 kHz

Testing:

The customer sent the parts to Ambrell pre-fluxed and preassembled. The part was placed into the coil and power was turned on. It took just 30 seconds for the part to reach brazing temperature.

Benefits:

-

Speed: Heating took 30 seconds (or less), which can"t be matched when using a torch. This client was using an old induction system from another vendor, and the Ambrell system provided considerably faster heating

-

Precise, repeatable heating: Induction is a highly repeatable process, unlike torch heating

-

Safety: There is no open flame with induction, which makes it a safer method of heating than torch heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000