Note: Brazing a Plumbing Union in Tight Quarters

Objective:

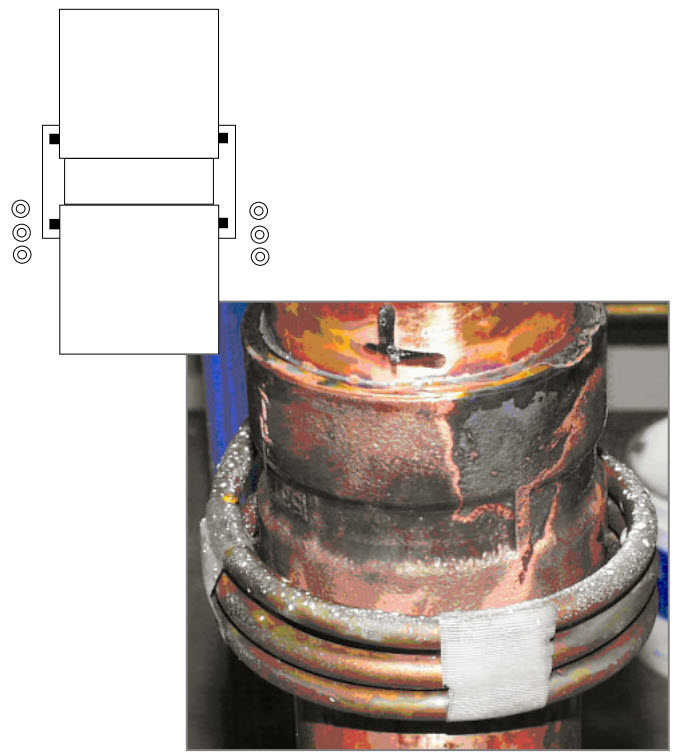

A copper-brass fluids union is brazed under constrained conditions (onboard a submarine), where access is limited and flame is not allowed.

End Product:

Plumbing union

Equipment:

Ambrell 7.5kW induction heating system including Coil: custom-designed multi-turn helical Workhead: two 1.5 μF capacitors, (Total 0.75 μF)

Materials:

Copper and brass plumbing components

Temperature:

750 °C (1380 °F)

Frequency:

245 kHz

Testing:

The coil is designed to maximize heating efficiency to reduce the cycle time and to reduce the heat conducted along the brass tubes. The assemblies are first cleaned and braze flux is applied to the entire surface of the assembly. The induction coil is slipped over the tube and the brass coupling is placed over the brass tubes. The flux is allowed to dry. The assembly is heated until the braze flows.

Benefits:

-

Ergonomics: Induction provides a reliable braze joint obtained under limited-access conditions

-

Economy: energy is applied only to the joint; little energy is lost to surrounding parts, air

-

Safety: flame is not used; no bottled gasses required

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000