Note: Brazing a Copper Tube & Brass Fitting

Objective:

To heat copper tubes and brass fittings for a brazing application; they had been using a torch.

End Product:

Brass & copper fittings

Equipment:

Ambrell EKOHEAT 15 kW, 50-150 kHz solid state induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Brass & Copper

Temperature:

1400 °F (760 °C)

Frequency:

97 kHz

Testing:

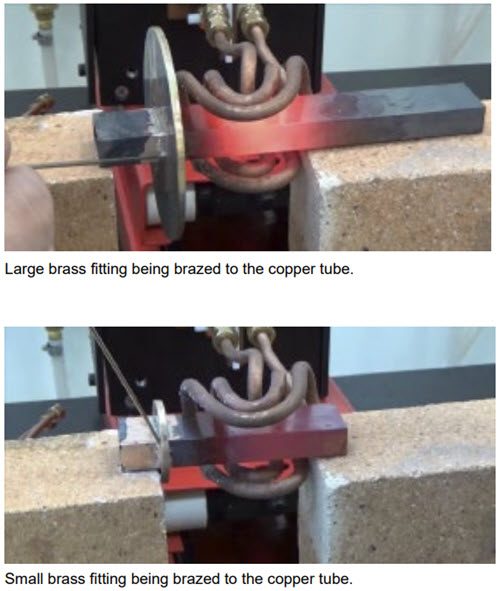

A custom-designed single-position multiple-turn U-shape coil was built to generate the required heating for this brazing application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part, which dissolves when the part reaches target temperature. The part achieved temperature for the braze to flow in under four minutes. It was also noted that the magnetic field of the coil was able to push the brass fitting during heating, so a fixture to hold the brass fitting in place was recommended.

Benefits:

-

Speed: Induction met the client"s time requirements.

-

Precision: Induction heats only the area that requires it for brazing.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating, which isn"t the case with a torch.

-

No Open Flame: Which results in a safer work environment.

-

Lab Expertise: THE LAB at Ambrell was able to design a heating solution that met their requirements.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000