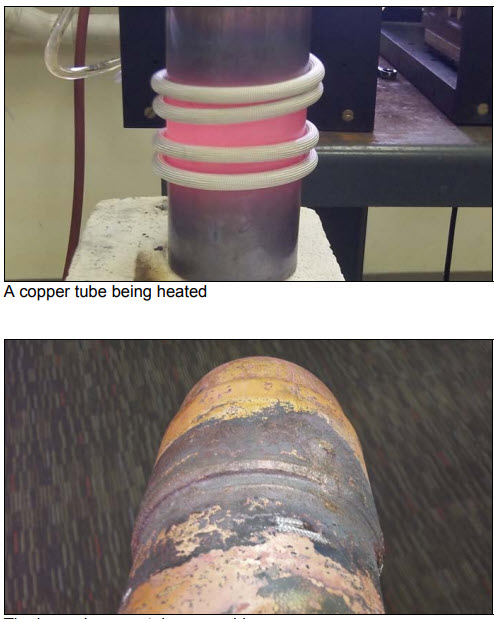

Note: Brazing a copper tube assembly

Objective:

To heat a copper tube assembly to 1450 °F for a brazing application with a portable induction heating system that will be used to repair leaking joints

End Product:

copper tube assembly

Equipment:

Ambrell EKOHEAT 15kW 50-150 kHz induction heating system equipped with a remote work head containing one 5.0 μF capacitor A multi-turn helical induction heating coil designed and developed specifically for this application

Materials:

Copper tube assemblies Silica sleeve to cover the copper Brass fittings for the coil Brazing alloy stick

Temperature:

1450 °F (800 °C)

Frequency:

120 kHz

Testing:

Testing confirmed the viability of heating a range of copper tube assemblies to 1450 °F for brazing applications. The client's key concern was ensuring that the portable system, which would reside on a cart, would be as light as possible while still capable of brazing tubes ranging from .5 in (12.7mm) to 1.5 in (38.1mm) in diameter. This system met those needs, as it heated the parts efficiently, and proved to be versatile with the range of part sizes tested.

Benefits:

-

Versatility: The proposed system was capable of heating a wide variety of tube assemblies

-

Weight: The system is light enough to be used on a cart

-

Speed: The system was able to meet the client"s time/productivity objectives

-

Part quality: The quality of the brazed assemblies was strong

-

Safety: Induction is flameless and introduces less heat into the environment than their previous heating method using a torch

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000