Note: Brazing a Copper Tube and Steel Plate

Objective:

To heat a copper tube and a steel plate for a brazing application; while this is a new process for the client, they also tested the process with a torch.

End Product:

Device with a soup can in shape

Equipment:

Ambrell EASYHEAT 6 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

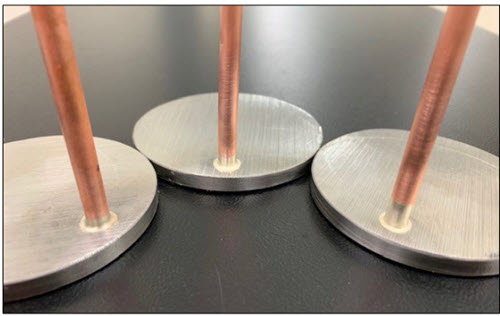

Copper tube (0.25 in/ 6.4 mm) steel plate (3 inOD x .25 inthick / 76.2 mm OD x 6.4 mm thick)

Temperature:

1300 °F (704 °C)

Frequency:

Testing:

A custom-designed single-position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part which dissolves when the part reaches the target temperature. It took 75 seconds to heat the sample to temperature. The frequency was set to 255 kHz.

Benefits:

-

Repeatability: This was one of the client"s top two priorities, and induction heating is significantly more repeatable than torch heating.

-

Quality: This was the client"s other top priority, which aligns with repeatability. Induction offers a more consistent solution which bodes well for quality.

-

Safety: Induction doesn"t introduce an open flame into the working environment like a torch.

-

Expertise: The client took advantage of THE LAB"s expertise to prove out their process.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000