Note: Brazing a Copper Tube and Brass Assembly

Objective:

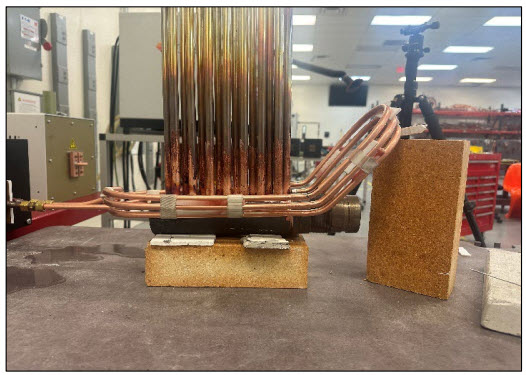

To heat a customer supplied copper tube and brass fitting assembly for a brazing application; the customer, a manufacturer of heat exchangers, had been manually brazing the assemblies.

End Product:

Copper tube and brass assembly

Equipment:

Ambrell EKOHEAT 50 kW, 5-15 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Copper tube and brass fitting assembly

Temperature:

1400 °F (760 °C)

Frequency:

15 kHz

Testing:

A custom-designed helical coil was built to generate the required heating for this brazing application. Initial tests were conducted to optimize power delivery to the assembly. Testing was also conducted to determine the coil setup. Lab testing showed that the heat time was 3-4 minutes for this application with a 50 kW power supply. The coil design allows for parts to be placed inside the heating zone and then easily removed, making the process more efficient for the client.

Benefits:

-

Speed: The client was able to braze the assembly faster than they would have with their torch heating process.

-

Safety & Efficiency: There is no open flame with induction heating, and it also introduces less heat into the work environment. It is also more efficient than most other heating methods such as torch heating.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating. Torch heating, on the other hand, is highly dependent on operator skill and consistency.

-

Lab Expertise: THE LAB at Ambrell designed a solution that met the client"s goals giving them peace-of-mind before investing in a system.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000