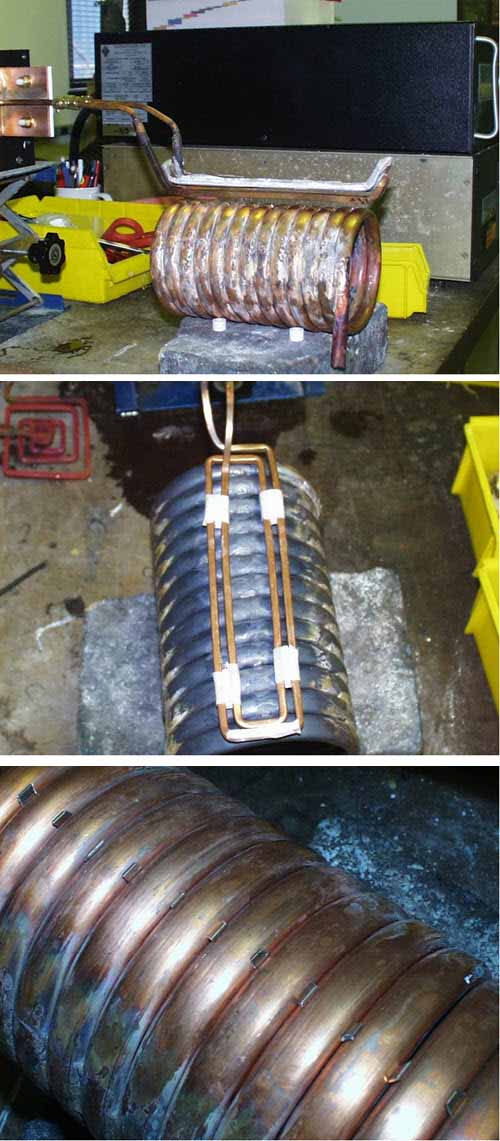

Note: Brazing a copper pipe assembly seam

Objective:

Heating a copper pipe assembly to 1350 °F (732 °C) for a brazing application.

End Product:

Copper pipe

Equipment:

Ambrell 8kW induction heating system, equipped with a remote workhead containing two 1.5Ä μF capacitors for a total of 0.75Ä μF An induction heating coil designed and developed specifically for this application.

Materials:

Copper pipe, silver phosphorous braze pieces

Temperature:

1350 °F(732 °C)

Frequency:

216 kHz

Testing:

A single position 2-turn pancake coil is used to generate the required heating for the application. A silver phosphorous braze is cut into small pieces and placed at each of 12 points that a junction is desired. The part is then placed under the coil and the power is turned on for 60 seconds to flow the braze. The customer is seam brazing copper pipes together. They will reduce the brazing of the seam down to15-30 seconds. This customer is currently using a torch, but is not getting uniform quality, and hopes to improve on this. Also, it is dangerous for the operator.

Benefits:

Reliable, repeatable aesthetically pleasing braze joint

Even distribution of heating

Faster, repeatable and consistent results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000