Note: Brazing a copper elbow tube assembly

Objective:

To heat a copper elbow 4 in (101.6 mm) OD and a stainless steel coupling to temperature in 180 seconds for a brazing application. The end result is flexible tubing for the construction industry.

End Product:

Flexible tubing

Equipment:

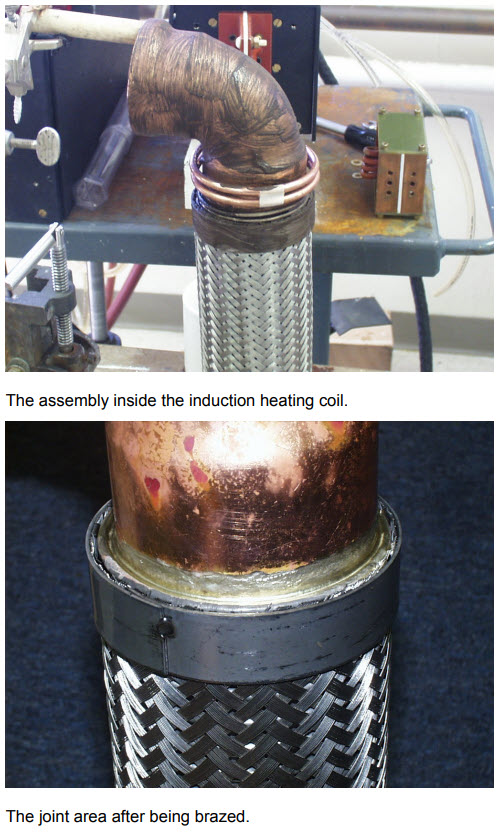

Ambrell EKOHEAT 10 kW, 50-150 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors A single position, two-turn helical induction heating coil designed and developed specifically for this application

Materials:

Copper elbow 4 in (101.6 mm) OD Stainless steel coupling Braze material

Temperature:

1250 °F (677 °C)

Frequency:

128 kHz

Testing:

Initial testing was conducted to optimize power delivered to the part. Two braze pre-forms were placed around the copper elbow, and the elbow and stainless steel coupling were fluxed. The elbow and coupling were assembled inside the coil and then heated. The joint was heated within 180 seconds, which met the client's objective.

Benefits:

-

Improved quality and repeatability: The client was using a torch, and induction offers more precise heating that is repeatable

-

Speed: Induction heating allowed the client to achieve the targeted heating time of 180 seconds

-

Superior efficiency: Induction heating applies heat only to the part, which means there's no wasted energy and cost savings are achieved when compared to a brazing torch

-

Safety: Unlike a torch, induction offers clean, flameless heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000