Note: Brazing a Carbide and Steel Assembly

Objective:

To braze a carbide insert into a steel tool; this was a new process for the client

End Product:

Steel tool

Equipment:

Ambrell EASYHEAT 2.4 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Carbide and steel part braze shims black flux

Temperature:

1400 °F (760 °C)

Frequency:

350 kHz

Testing:

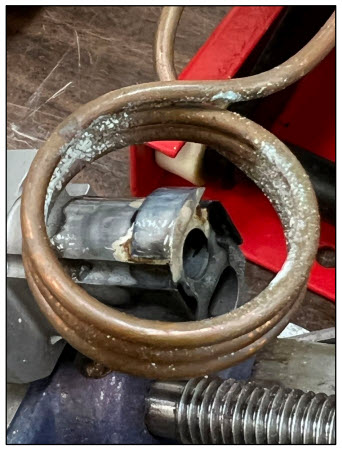

A custom-designed single-position multiple-turn helical coil was built to generate the required heating for this brazing application. Initial tests were conducted to optimize power delivery. Temperature indicating paint was used to determine the heating time. Two braze shim preforms along with black brazing flux was used during testing. It took 15-20 seconds to heat the sample to temperature and melt the braze alloy. An external ceramic tube insulator will maintain pressure on the parts during heating.

Benefits:

-

Speed: The client was able to braze their parts faster than they would have with the other processes they evaluated. Precision: Induction heats only the area of the part that requires it.

-

Safety & Efficiency: There is no open flame with induction heating, and it also introduces less heat into the work environment. It is also more efficient than most other heating methods.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating.

-

Lab Expertise: THE LAB at Ambrell designed a solution that met the client"s goals giving them peace-of-mind before investing in a system.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000