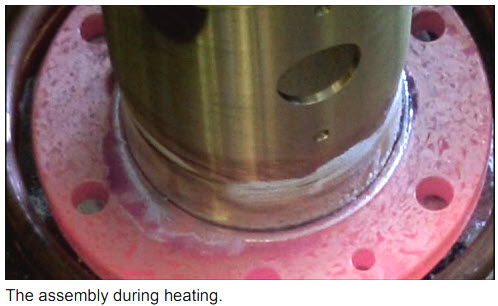

Note: Brazing a brass tube and flange

Objective:

To heat a brass tube and a brass flange for a brazing application; the client is replacing a torch

End Product:

a brass tube and flange assembly

Equipment:

Ambrell EKOHEAT 10 kW, 50 to 150 kHz induction heating system equipped with a remote workhead containing four 1.5 μF capacitors for a total of 4.5 μF. A two-turn helical induction heating coil developed specifically for this application

Materials:

- 3 in (76.2 mm) OD brass tube

- 5.25 in (133 mm) brass flange

- White flux

- Customer supplied braze alloys

Temperature:

1250 °F (677 °C)

Frequency:

70 kHz

Testing:

Application engineers determined placing a turn that is targeted to the tube inside the part would optimize heating for this application. This heats the tube while the flange is being heated enabling both parts to achieve the required temperature concurrently. With the 10C EKOHEAT power supply, the parts heated to required temperature within 120 seconds.

Benefits:

-

Speed: Induction is able to rapidly heat the parts to temperature

-

Repeatability: Induction is highly repeatable, while a torch presents inconsistent results to the client

-

Safety: Induction is a comparatively efficient and flameless method of heating

-

Expertise: The Ambrell Applications Lab used their expertise to create the right solution for the client

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000