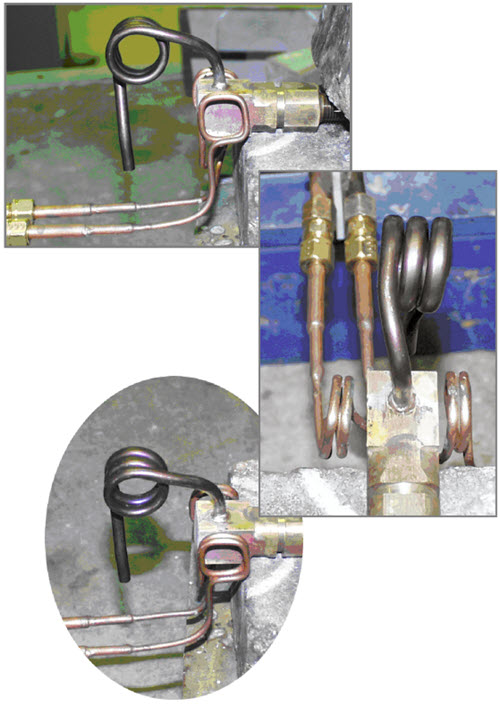

Note: Brazing a Brass Trap Block

Objective:

Block is heated to 1400 °F to braze trap tube to assembly

End Product:

Brass trap tube

Equipment:

Ambrell 8.3kW induction heating system including Coil: custom-designed 2-turn split-helical Workhead: contains two 1.0 μF capacitors (0.5 μF total)

Materials:

brass block and pre-formed tubes braze pre-forms

Temperature:

1400 °F (760 °C)

Frequency:

357 kHz

Testing:

The brass parts, braze pre-form and flux are assembled and located within the custom-designed coil. Induction heating of the joint is accomplished in 45 seconds.

Benefits:

-

Economy: induction heats only the material within the coil; no energy is wasted heating the surrounding materials and air; no flame or gasses required for heating

-

Control: process lends itself to the use of braze pre-forms; process easily adapted to automation

-

Efficiency: energy is expended only during the joint formation

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000