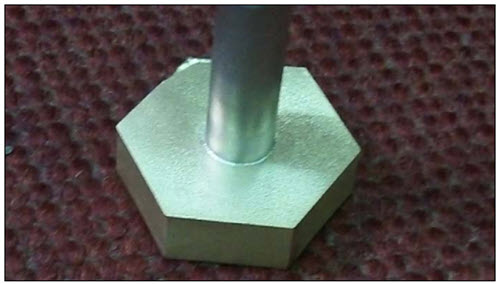

Note: Brazing a brass screw cap and a steel tube

Objective:

To heat a brass hex screw cap and a steel tube

End Product:

Brass steel assembly

Equipment:

Ambrell EKOHEAT 15 kW, 50 to 150 kHz induction heating system equipped with a remote workhead containing four 1.5 uf capacitors for a total of 1.5 uf A four-position, two-turn helical induction heating coil designed and developed specifically for this application

Materials:

Screw cap Steel tube Braze rings Flux

Temperature:

1400 °F (760 °C)

Frequency:

109 kHz

Testing:

White brazing flux was used on the parts. Samples were assembled using the braze rings, a batch of four samples were heated for 60 seconds, the braze flowed, and an aesthetically pleasing joint was created. The process met the client's time objective of 15 seconds per part. A faster heating time is not recommended due to the limitations of thermal conduction of brass to the center of the part

Benefits:

-

Speed: Induction enabled the brazing process to be completed at a rate of 15 seconds per part

-

Consistency: Induction enables consistent joint quality, which a torch often doesn"t deliver

-

Safety: There is no open flame with induction, so it"s a safer heating option than other options such as torch heating

-

Efficiency: Induction delivers heat only where it"s required, making it more efficient than many competitive heating methods

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000