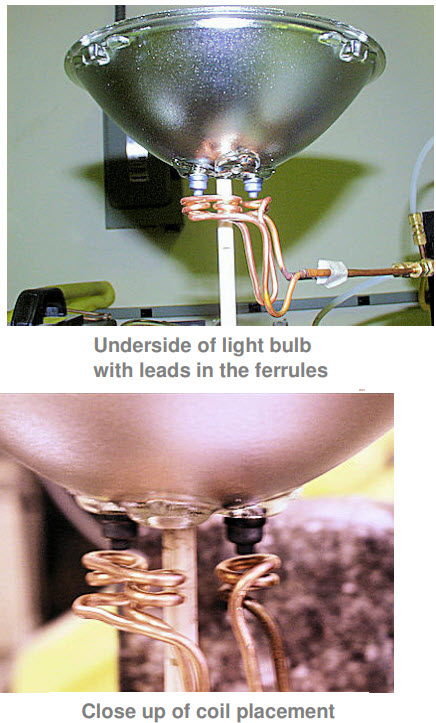

Note: Braze a lead to a ferrule (automobile PAR bulb)

Objective:

Braze a nickel plated steel mount lead to nickel steel ferrule in a PAR bulb assembly

End Product:

PAR bulb assembly

Equipment:

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 1.2 μF capacitors for a total of 0.5 μF An induction heating coil designed and developed specifically for this application.

Materials:

PAR light bulb, mount leads 0.075 in (1.9mm) to 0.09 in (2.28mm) in dia. ferrules are 1.25 in (31.75mm) apart center to center, braze powder & flux

Temperature:

1150 °F (621 °C)

Frequency:

357 kHz

Testing:

A split helical coil heats 2-3 ferrules at a time. The ferrules are filled with flux and the mount leads are placed inside the ferrules. Heat is applied for 3 seconds to allow the flux to flow followed by 2 seconds of dwell time to allow indexing of the part. Heat is applied for 3 more seconds to allow the braze to flow and capture the mount leads.

Benefits:

-

Decreased production time

-

Decreased energy costs

-

Uniform & exact heat placement

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000