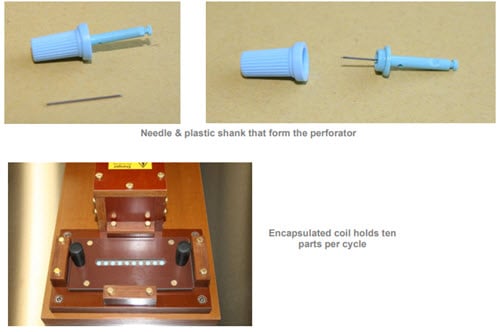

Note: Bonding a stainless steel needle to a plastic shank

Objective:

To heat a stainless-steel needle within a plastic shank to form a dental perforator

End Product:

Dental perforator

Equipment:

Ambrell EASYHEATTM 1.2 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Stainless steel needle 0.017” (0.43 mm) OD, and plastic shank.

Temperature:

356 ° F (180 °C)

Frequency:

359 kHz

Testing:

A pancake/plate coil was used in this application. Ten assemblies were placed in the coil and power was applied for 1 second to melt the plastic to the stainless steel needle and achieve a 5 kg pull out strength. 3,000 parts could be processed per day with this setup.

Benefits:

-

Consistent, repeatable and reliable bond

-

More stable and reliable bond compared to ultra-sonic heating

-

Faster process time

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000