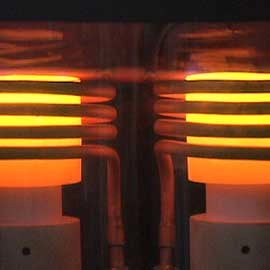

Induction Brazing in a Controlled Atmosphere

- Home

- How It's Used

- Atmosphere Controlled Brazing

Why braze in a controlled atmosphere?

Induction brazing in controlled oxygen-free atmospheres under normal or close-to-normal atmospheric pressure is known as atmospheric brazing, allowing for reduced oxidation and improved control over the process.

Benefits of Induction Brazing in a Controlled Atmosphere

-

Meets tight production tolerances with precise localized heat to small areas creating pinpoint accuracy

-

Increases production rates with faster heating cycles

-

Reduces defect rates with repeatable, reliable heat

-

Eliminates variability from operator-to-operator, shift-to-shift

-

Maintains metallurgical characteristics of the individual metals

controlled atmosphere brazing Application Notes

Select from our collection of controlled atmosphere brazing notes, developed over 40 years supporting our customers. Read how we helped to solve their process heating challenges!

Brazing Steel Hydraulics Fittings & Tubes

Brazing Steel Hydraulics Fittings & Tubes

Braze steel fittings and tubes in an atmosphere to make hydraulic fittings within a targeted heating time of under 150 seconds.

Brazing a small gas delivery assembly

Brazing a small gas delivery assembly

This is a new part for the customer and they are developing the manufacturing process for it. The customer is interested in using induction heat for their process because they are looking for finished parts which are clean and not contaminated by any flux material. By using induction to braze the part and by doing the braze under a hydrogen atmosphere, the customer can produce brazed parts with no oxidation...

Braze a thin walled tube to a steel cap

Braze a thin walled tube to a steel cap

A single turn helical coil is used to heat the quartz tube and the tube assembly. The tube assembly is held in place inside the quartz tube by a copper fixture and hydrogen is fed into the quartz tube...

Braze Copper Tube to Brass Fitting

Braze Copper Tube to Brass Fitting

To use induction heating to braze a copper tube to a brass fitting using a preform braze wire.

Brazing Copper Tube Assemblies

Brazing Copper Tube Assemblies

To heat a copper tube assembly in an inert atmosphere to 1450 °F within 45 seconds for brazing without flux or acid wash clean-up.

Brazing Hydraulic Hose Assemblies

Brazing Hydraulic Hose Assemblies

To heat a steel hydraulic hose fitting in an inert atmosphere to 2200 °F within 7 seconds for brazing without any carbon buildup.

-

What parameters can limit controlled amosphere brazing with induction?

Brazing within an atmosphere is done by using a flux. This flux is not wished for in some applications the product is used for due to its corrosive nature. In addition brazing in atmosphere will result in more cleaning requirements after the joint was created

-

Why is atmosphere brazing beneficial in cold atmospheres?

Cold atmospheric brazing is typically considered low temperature joining of two metals at temperatures upto 500 degrees Celsius. This results in faster heat cycles, less power requirement, quicker cooling cycles and less distortion due to the lower temperature input.

-

What are the benefits of atmosphere brazing?

Due to the fact that brazing in an atmosphere is less complex than in an inert atmosphere the production rate is greatly increased. In addition less complex investment is required as it does not require specialized equipment to create an inert atmosphere or vacuum. Brazing in atmosphere is more versatile as setup changes are easily conducted in order to produce different parts

Our Systems for controlled atmosphere brazing with Induction

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

Headline

Add your content here.

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

![]() Directions

Directions

T: +1 585 889 9000

F: +1 585 889 4030

Contact Sales

Contact Orders

Contact Service

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

![]() Directions

Directions

T: +31 880 150 100

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

AMBRELL Ltd.

Front Suite, 1st Floor, Charles House

148-149 Gt Charles Street

Birmingham, B3 3HT

United Kingdom

T: +44 1242 514042

F: +31 546 788 154

Contact Sales

Contact Orders

Contact Service

-

What Parameters can Limit Atmosphere Brazing with Induction?

Brazing within an atmosphere is done by using a flux. This flux is not wished for in some applications the product is used for due to its corrosive nature. In addition brazing in atmosphere will result in more cleaning requirements after the joint was created

-

Why is Atmosphere Brazing Beneficial in Cold Atmospheres?

Cold atmospheric brazing is typically considered low temperature joining of two metals at temperatures upto 500 degrees Celsius. This results in faster heat cycles, less power requirement, quicker cooling cycles and less distortion due to the lower temperature input.

-

What are the Benefits of Atmosphere Brazing?

Due to the fact that brazing in an atmosphere is less complex than in an inert atmosphere the production rate is greatly increased. In addition less complex investment is required as it does not require specialized equipment to create an inert atmosphere or vacuum. Brazing in atmosphere is more versatile as setup changes are easily conducted in order to produce different parts

-

Your induction controlled atmosphere brazing question..