Note: Surface hardening of steel screws

Objective:

Rapid surface hardening of steel screws

End Product:

Steel screws

Equipment:

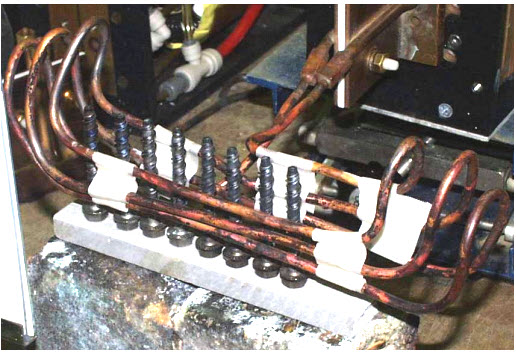

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 0.3Ä μF capacitors for a total of 0.17Ä μF An induction heating coil designed and developed specifically for this application.

Materials:

Steel screws .25 in (6.3mm) diameter

Temperature:

932 °F (500 °C)

Frequency:

344 kHz

Testing:

A three-turn channel coil is used to heat 9 screws at a time. Power is applied for 3 seconds to reach 932 °F (500 °C) and achieve the required hardness. The screws travel through the coil head down in an automated system at a rate of 200 screws per minute

Benefits:

-

Precise application of heat

-

Faster process time and production rates

-

Ability to incorporate into existing production lines

-

Repeatable, consistent results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000