Note: Induction Annealing Springs for Stress Relief

Objective:

To use induction annealing to stress-relieve springs used in garage door openers.

End Product:

Garage door springs

Equipment:

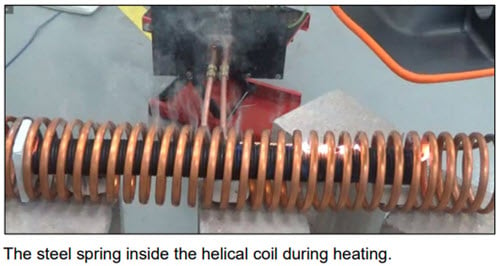

Ambrell EKOHEAT 50 kW, 15-45 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Steel springs

Temperature:

600 °F (315.6 °C)

Frequency:

19 kHz

Testing:

A specially designed multi-turn helical coil was used to provide the required heat to the spring. Initial tests were conducted to optimize the power delivered to the part and to understand the heating patterns. Testing was successful, with a time-to-heat of 15 seconds. This client had been using an oven but was interested in changing to induction heating.

Benefits:

-

Speed: The client will be able to save time with induction given the process that is involved with oven heating, especially when oven ramp up time is considered.

-

Space: Induction requires less space than an oven and the workhead can be placed away from the power supply, potentially freeing up even more floor space.

-

Repeatability: Induction delivers the same result every single time, making it an ideal heating process for repeatability/quality.

-

Efficiency: Induction is highly efficient only heating where required and it is instant on/off, making it a greener choice.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000