Note: Annealing Stainless Steel Braids

Objective:

To heat stainless steel braids for an annealing application in the medical device industry.

End Product:

Steel braid

Equipment:

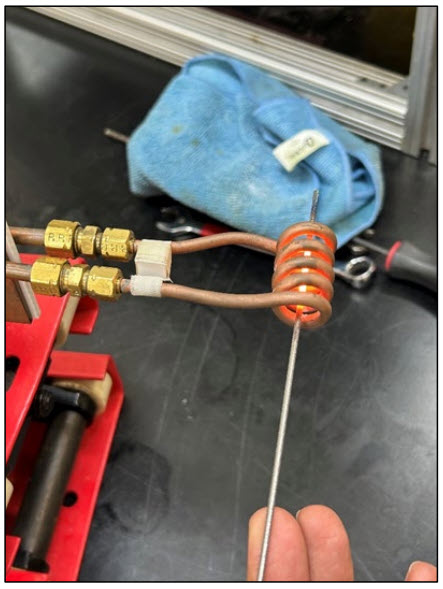

Ambrell EASYHEAT 6 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

Stainless steel braids

Temperature:

1,000 °F (538 °C)

Frequency:

335 kHz

Testing:

A specially-designed multiple-turn helical coil was used to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the art. Once a satisfactory heat pattern was achieved in the time frame allowed, samples were run at multiple settings. Heating took just 2-5 seconds depending on the sample used, meeting the client’s requirements. This application is a new process for a high-volume production environment.

Benefits:

-

Speed: Induction met the client’s time requirements.

-

Space: Induction is friendly from a space perspective in a production environment as the power supplies are compact and the workhead can be placed away from the power supply.

-

Repeatability: Induction delivers the same result every single time when using the same part, making it an ideal heating process for production.

-

Efficiency: Induction is highly efficient, only heating where required and it is instant on/off, making it a greener choice.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000