Note: Annealing Brazing Wire

Objective:

Anneal a brazing wire for preform production.

End Product:

Brazing Wire

Equipment:

- Ambrell 3 kW induction heating system equipped with a remote workhead with one 1.0 µF capacitor, and a 4-20 mA input controller to aid in voltage ramping.

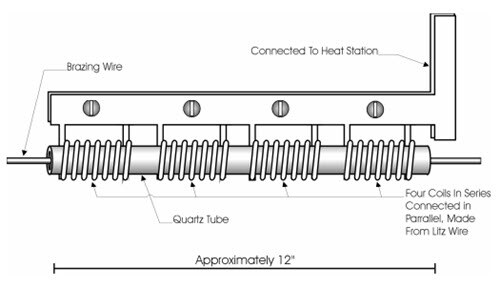

- An induction heating coil designed and developed specifically for this application.

Materials:

Copper Nickel Silver 2774 Alloy rod 0.070" (1.8mm) diameter.

Temperature:

650ºF (343.3ºC)

Frequency:

281 kHz

Testing:

A unique helical coil consisting of four consecutive coils connected in parallel with a quartz tube lining is used to heat the wire to 650ºF (343.3ºC) for annealing.

Benefits:

Induction heating provides:

-

Higher productivity of 27’ (8.2m) per minute

-

Reduction in surface oxidation & scaling

-

Consistent, repeatable results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000