How Researchers and Universities Use Induction Heating

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

3/19/18 4:32 PM

A company that specializes in flow control solutions turned to THE LAB at Ambrell to heat a steel valve to 400 °F (204 °C) for a welding preheating application. This process is new to the customer and they turned to induction because of the potential for rapid heating and reduced cycle times.

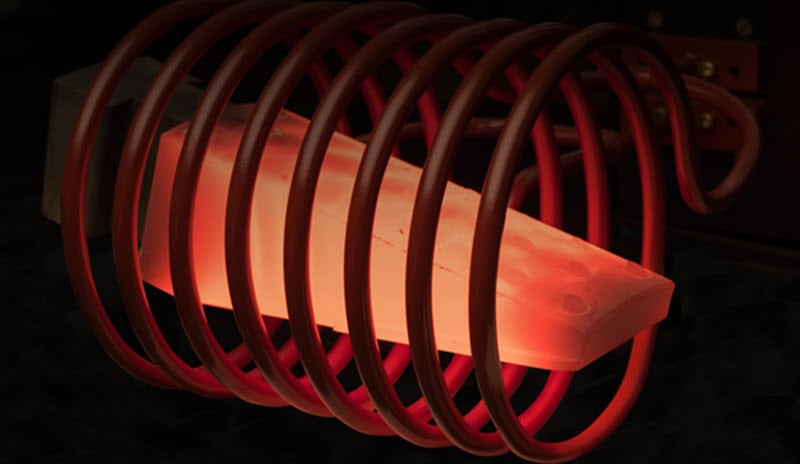

THE LAB determined that an EKOHEAT® 10 kW induction heating system would be right for this welding preheating application, and they designed a multiple-turn internal bore helical coil for the application. Temperature indicating paint was applied to the part and heating began. It was observed that the depth to which the coil was inserted was critical to heating both above and below the weld joint. For this application, heating can occur with a single coil in less than five minutes.

Using induction for preheating results in significantly faster time-to-temperature for users. On some applications with thicker parts, it can literally shave hours from the cycle time. Heating uniformity, quality and safety are among the other reasons companies are increasingly looking at induction heating for this application.

If you have a heating application you'd like tested, learn about complimentary applications testing from THE LAB at Ambrell.

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Objective A company had been using a flame for brazing copper assemblies to make electrical components, but they contacted THE LAB at Ambrell because...

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely...