Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

1 min read

Brett Daly

12/18/20 3:14 PM

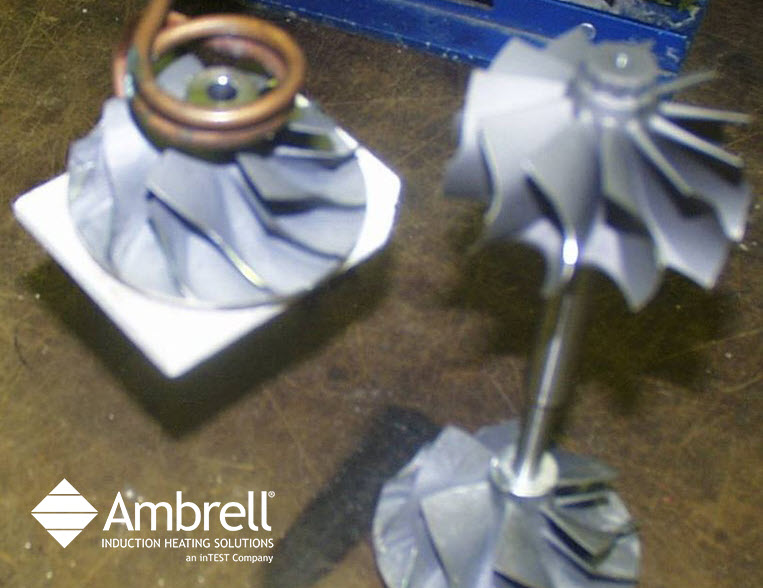

A client contacted THE LAB at Ambrell needing to heat aluminum impeller blades to 200 ºF (93 ºC) and shrink fit them onto shafts. THE LAB determined that an Ambrell EASYHEATTM 3.5 kW, 150-400 kHz induction heating system would be best for this induction shrink fitting application based on the client's requirements. The frequency for the application was determined to be 255 kHz.

A split two-turn helical coil was used to evenly heat the opening on the impeller blade. The impeller blade was heated for 20 seconds to reach the target temperature of 200 ºF (93 ºC). The impeller blade was then removed from the coil and slipped over the shaft to complete the shrink fitting application.

For this application, induction heating offered several advantages. It provided fast heating which saved power and time. This resulted in a reduced cycle time for this application. It's also a clean source of heat that delivers less heat into the work environment than a torch and takes up less space than an oven. Finally, induction is accurate and highly repeatable, which boosts quality.

THE LAB at Ambrell has a significant amount of experience with induction shrink fitting applications like this one. To learn more about free application testing, visit our page with more information about THE LAB or contact us today to get the process started.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...