Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

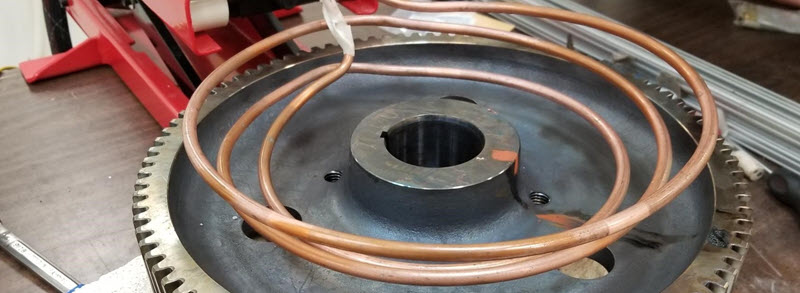

A manufacturer of power generation equipment approached THE LAB at Ambrell with a shrink fitting application. They had been shrink fitting a magnetic steel gear with an oven, but that oven took over two hours to heat the gear to 550 °F (288 °C). Their hope was that induction could significantly reduce that time, which would increase their productivity and enable more throughput. They sent in their parts to Ambrell and took advantage of complimentary applications testing.

THE LAB determined that an EASYHEAT 2.4 kW, 150-400 kHz induction heating system with a single position multiple-turn pancake coil would be the right solution based on their requirements. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part, which dissolves when the part reaches the target temperature. It was observed that it took 45 minutes to heat the sample to temperature. The coil can also be placed beneath the gear to allow oil to burn-off without condensing on the coil.

For this client, speed was the most significant motivator to switch from an oven to induction. Going from two hours to 45 minutes provides a significant time savings which enables them to be more productive. Footprint is another advantage since ovens tend to be large, while induction is more space efficient and the workhead can be placed away from the power supply. Finally, efficiency is another factor as induction can provide much more targeted heating than an oven can offer.

THE LAB at Ambrell has considerable experience with induction shrink fitting applications. Visit our induction shrink fitting page to get a sampling of additional shrink fitting applications assessed by THE LAB. And, to learn more about free application testing, visit our page on THE LAB or contact us today to get the process started.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...