Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

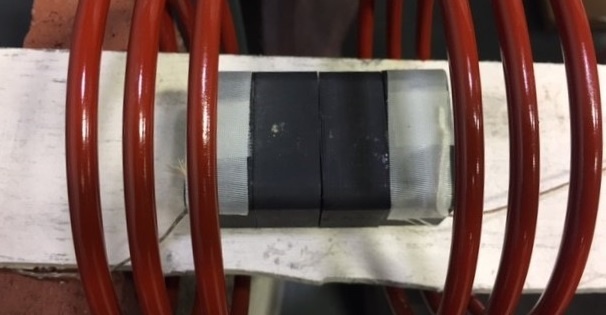

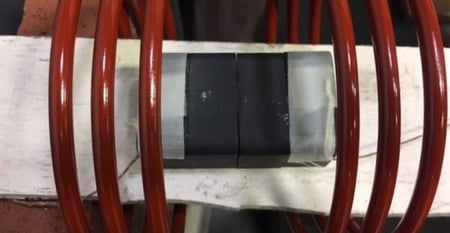

This application involved heating four steel laminate parts (c-lams) for a pre-heating application in the automotive industry. The parts, which are inserts, are heated simultaneously before robotic pick-and-place for plastic overmolding. The client was looking to change to induction from resistance heating.

An EKOHEAT 15 kW/50-150 kHz system was chosen for this application. A thermocouple was attached to the top surface of each outer c-lams in the stack for temperature monitoring. The parts were successfully heated to the target temperature of 190°C (374 °C) within 10.0 seconds with the EKOHEAT, which met the client's objective.

Speed, repeatability and energy efficiency led the client to consider induction heating over resistance heating. The guidance and expertise from THE LAB at Ambrell was another critical factor in their decision. To learn about other preheating applications evaluated by THE LAB at Ambrell, visit our website.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...