Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

If you're wondering, "why should I use induction soldering?" then you've come to the right place. Induction soldering is an induction process in which two separate pieces are fused together using a filler metal or other material. The filler metal varies depending on the other components being joined, but the most common fillers for induction soldering include alloys such as tin-silver, tin-zinc, and tin-lead.

More Induction Soldering Application Notes

Soldering differs from brazing because it is performed at lower temperatures. When compared to brazing, soldering may have a slightly weaker joint, but that can be preferable for some applications like small components. Soldering differs from welding because it does not involve the melting of joints. There are a number of benefits that come with using induction for soldering applications. Here are just a few:

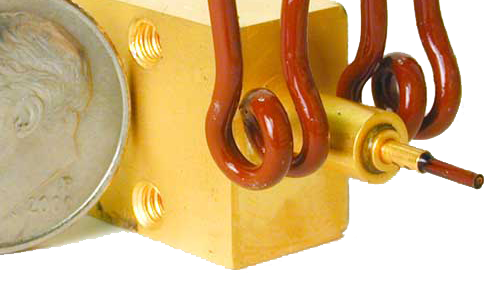

An induction heating system typically consists of three parts: the power unit, the work head, and the work coil. First and foremost, induction is a rapid method of heating. Depending on the work piece and system being used, the process can take just seconds. So if you're hoping to solder metals quickly, induction is a great choice.

Induction is a precise method of heating, which makes it a great method for soldering. Once the process is set up, you can expect the same result time after time. It helps minimize the odds of inconsistencies which you might see with a soldering iron or torch.

Induction heating for soldering enables you to control the process thanks to induction's precise heating while also avoiding thermal stress.

Ultimately, the efficiency of an induction heating system for a specific application depends on four factors:

the characteristics of the part itself

the design of the inductor

the capacity of the power supply

the amount of temperature change required for the application

Understanding the basic information about induction soldering can help you determine whether or not it's suitable for your needs, so next time you're asking yourself, "why should I use induction soldering?" you'll have some background info.

For more information about induction soldering and other induction equipment for sale, contact Ambrell Corporation.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...