Induction Brazing an Aluminum Assembly

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services:

Services: More

Learn:

Learn: More

About:

2 min read

Brett Daly

8/12/22 10:43 AM

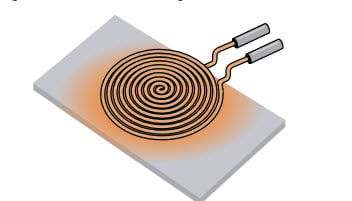

Induction coil design has a major impact on process efficiency and final part quality, and the best coil design for your product largely depends on your application. Certain coil designs tend to work best with specific applications, and a less than optimal coil-application pairing can result in slow or irregular heating, higher defect rates, and lower quality products.

Several applications rely on part movement with the help of conveyors, turntables, or robots. A properly designed induction coil incorporates these individual handling requirements without the loss of heating efficiency.

Higher frequencies are used for applications like brazing, soldering, annealing or heat treating, where surface heating is desired. Lower frequencies are preferred for applications requiring through-heating of the parts to the core like forging and die heating.

Higher power densities are required for short cycle heating applications requiring high temperatures. Higher power densities may also be required to keep the hot zone confined to a small area, reducing the heat affected area.

Start with understanding where the heat needs to be generated in the part to perform the process, and then design the coil to achieve the heating effect. Similarly, frequency selection will depend on the induction heating application you’ll be using for your part.

Want to learn more? If you’d like to get an experienced set of eyes on your induction application, our team is available for consultation.

Objective A company wanted to assess using induction heating for their aluminum assembly brazing process, and contacted THE LAB at Ambrell to utilize...

Induction heating is a process that uses electromagnetic fields to heat electrically conductive materials. It has been used in numerous industries...

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...