How Researchers and Universities Use Induction Heating

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Applications

Applications: More

Applications: More

Industries:

Industries: More

Industries: More

Industries: More

Products:

Products: More

Services: More

Learn:

Learn: More

About:

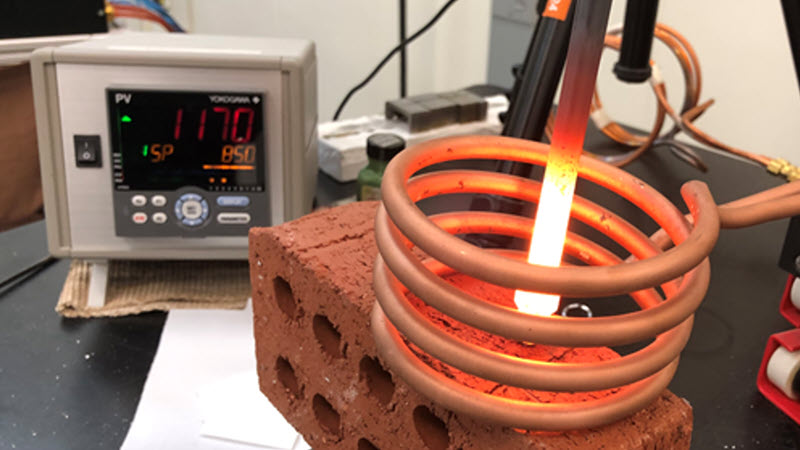

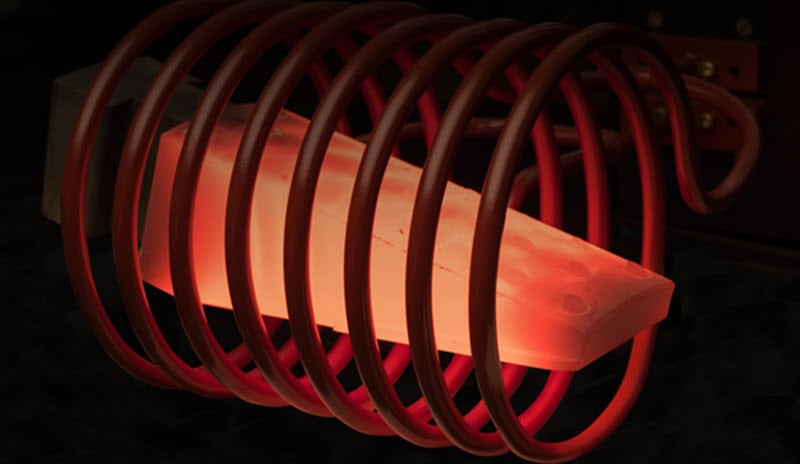

A client came to THE LAB at Ambrell looking to braze steel fittings and tubes within a targeted heating time of under 150 seconds to make hydraulic fittings. THE LAB determined that an Ambrell EKOHEAT® 15 kW, 50-150 kHz induction power supply would best meet their requirements. A custom-designed single position multiple-turn helical coil was built to generate the required heating for this brazing application.

Initial tests were conducted by THE LAB at Ambrell to optimize the power delivered to the part. Initial tests were also conducted to determine the rate of heating and the heating pattern achieved. Once a satisfactory heating pattern was achieved, parts were heated to the target temperature within 120 seconds. This, of course, met the client's timing objectives, and the parts met their quality requirements.

Induction offers a number of advantages to this client and others that have brazing applications. Speed is one considerable advantage of induction when compared to most other heating methods, and in this case it exceeded the client's requirements. The client also needed to braze in an atmosphere, which induction is well-suited to do. Induction is also extremely repeatable, so you can expect the same result time after time. Finally, THE LAB's expertise and ability to design a process that met their requirements was also a significant factor in choosing Ambrell.

Visit our brazing page to see a wide array of brazing applications. And, if you have an application you'd like assessed, contact THE LAB to take advantage of complimentary induction heating application testing from our expert applications team. Don't forget, THE LAB recently introduced Virtual Lab Service, where you can experience lab testing live from the comfort of your office.

Induction heating, a process that uses electromagnetic induction to heat electrically conductive materials, is often thought of for large industrial...

Objective A company had been using a flame for brazing copper assemblies to make electrical components, but they contacted THE LAB at Ambrell because...

Induction heating is a highly efficient and versatile technology with numerous industrial applications. Unlike traditional heating methods that rely...